Contact

Write to Us And We Would Be Happy to Advise You.

Do you have any questions, or would you like to speak directly with a representative?

By hqt

Membrane switches are an essential component of many electronic devices. They allow for the control and input of information, making them a crucial part of the user experience. However, when it comes to the cost of a membrane switch, there are several factors that can influence the final price. In this article, we will explore three factors that affect the cost of a membrane switch and provide insight into how you can optimize your membrane switch design for cost-effectiveness.

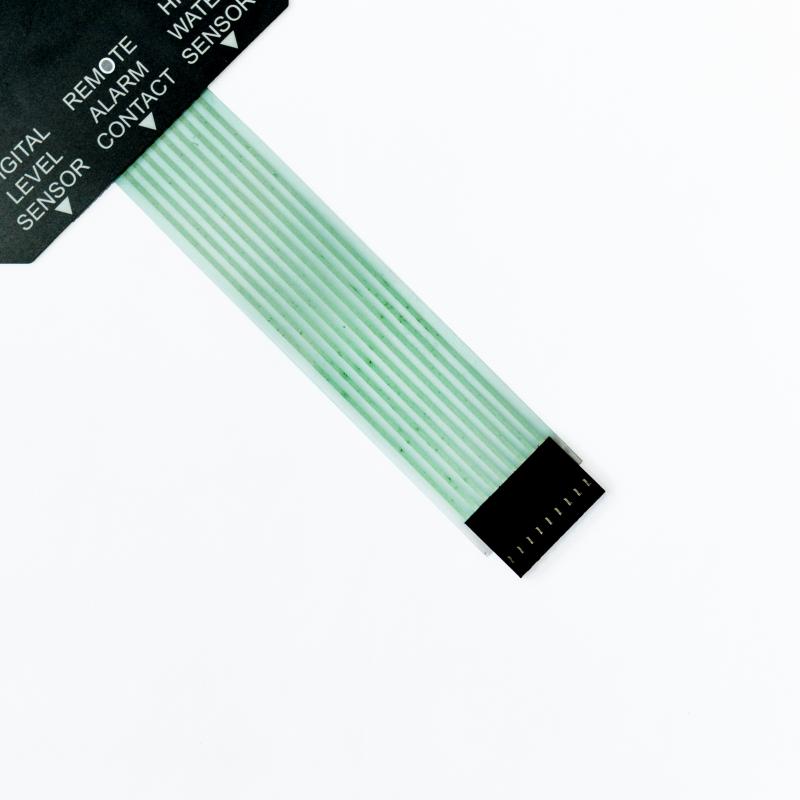

The materials used in the construction of a membrane switch are one of the most significant factors that affect its cost. Membrane switches are composed of various layers, including the graphic overlay, the adhesive, and the circuit layer. The type and quality of materials used for each layer can significantly impact the final cost.

For example, some graphic overlay materials, like polycarbonate or polyester, are more expensive than others, such as PVC. Additionally, the choice of adhesive can also influence the cost, with specialty adhesives often coming at a higher price. Lastly, the thickness and complexity of the circuit layer can also add to the overall cost of the membrane switch.

The complexity of the membrane switch design can also affect its cost. A more complex design may require additional layers, printing processes, and assembly steps, which can all add to the final cost. In contrast, a simpler design with fewer layers and fewer colors will typically be less expensive.

To optimize the cost-effectiveness of a membrane switch, it is essential to work with an experienced design team that can help you streamline your design without sacrificing functionality.

The quantity of membrane switches ordered can also influence their cost. In general, the more membrane switches ordered, the lower the cost per unit. This is because the fixed costs, such as setup and tooling, are spread across a larger number of units, making each individual switch less expensive.

To maximize cost-effectiveness, it is recommended to order membrane switches in larger quantities. However, it is essential to balance quantity and demand to avoid excess inventory or production delays.

In summary, the cost of a membrane switch can be influenced by several factors, including the materials used, the complexity of design, and the quantity ordered. To optimize the cost-effectiveness of your membrane switch, it is essential to work with an experienced design team, choose the most appropriate materials for your application, and balance the quantity ordered with demand. By carefully considering these factors, you can develop a membrane switch that meets your needs while remaining cost-effective

Do you have any questions, or would you like to speak directly with a representative?