Understand the needs of customers, let customers understand the impact of materials and design on products, and determine high value-added (increase market competitiveness) options, make suitable customer solutions, improve design drawings, and let customers confirm, produce, and QC detect packaging.

Understand the needs of customers:

Niceone-Keypad’s team will understand the customer’s product application direction and budget expenditure, and give customers the most suitable first draft design drawings of their products. The design and material selection of medical equipment is far from the design and material selection of marine equipment. In order to facilitate customers’ understanding, Niceone-Keypad has made a document on the impact of materials and design choices on products.

Material:

How Graphic Overlay is completely designed.

First understand the customer’s product and needs: The customer’s Graphic Overlay application environment and needs are put in the first place because the design and price factors of the product are determined.

Application environment – material selection

Application environment of Graphic Overlay:

You can simply use four logos for a simple overview:

* Temperature: Temperature has the greatest impact on the use of Graphic Overlay is adhesive.

From 10 to 60 degrees Celsius, you can choose DT adhesive made in China or Nitto adhesive made in Japan. This type can satisfy.

-20 to 100 degrees Celsius requires the use of 3M Adhesive.

* Indoor: Indoor problems are mainly the problem of anti-glare and avoiding button operation errors.

Overlay opted for F or V series of matte Polyester materials made by Autotex (which are non-reflective), or EB series of glare materials but printed with an anti-glare coating. And Polycarbonate is also a good choice.

* Outdoor: Outdoor problems are mainly long-term UV radiation and waterproof problems.

UV:

Overlay needs to choose HP92W, UV-resistant Silicone Rubber Keypad or Kotutai’s XE material as the material of Graphic Overlay.

Waterproof problem:

Choose Adhesive or Overlay with strong adhesion and choose Silicone Rubber Keypad as the waterproof panel. In terms of structure, you can choose a waterproof frame structure or a structure surrounded by silicone.

* Medical environment: There are many bacteria and corrosive liquids in the medical environment.

The panel material is best to choose antibacterial AM series Ketutai or antibacterial Silicone Rubber Keypad.

* Military environment: Harsh external environment and even high vibration environment occur from time to time.

Materials can be selected from well-known brands of Ketutai and 3M adhesive paper. High vibration proves that the original electronic parts of the product need to be able to endure high-intensity frequency vibration, and various electronic parts that require PCB and FPC as circuit welding can pass this kind of problem.

* Kitchen environment: oil pollution and high temperature need to be considered.

Choose 3M Adhesive and regular Polyester to fully meet the design requirements.

* Navigation environment: mainly long-term ultraviolet radiation and waterproof problems.

UV:

Overlay needs to choose HP92W, UV-resistant Silicone Rubber Keypad or Kotutai’s XE material.

Waterproof problem:

Choose Adhesive or Overlay with strong adhesion and choose Silicone Rubber Keypad as the waterproof panel. In terms of structure, you can choose a waterproof frame structure or a structure surrounded by silicone.

Design:

What does a Graphic Overlay design need?

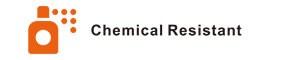

The following table shows some design points of Graphic Overlay:

1. Outline stroke is greater than or equal to 1.5mm.

2. The window stroke is greater than or equal to 0.5mm.

3. The distance between the punching hole and the window is 3.0mm.

4. The punching distance is greater than 3.0mm from the edge.

5. The distance between punching and punching is greater than or equal to 2.0mm.

6. Three-color transfer stroke thickness greater than or equal to 0.5mm.

7. The position of the button to the window is greater than or equal to 3.5mm.

8. The key interval is greater than or equal to 3.0mm.

9. Punching edge stroke is greater than or equal to 1.5mm.

10. The key interval is greater than or equal to 3.0mm.

The rest of the points:

1. Editable vector files. The thickness of the line needs to be greater than 0.1mm before it can be printed.

2. Detailed Pantone color number, RAL color number or Master Color as a color reference template to design colors for Overlay.

3. Considering the usage: Glare, ultraviolet, antibacterial, scratch resistance, etc. need to be customized according to the situation. The glare problem requires the use of matte inks or matte materials, and UV-resistant polyester and polycarbonate need to be considered. Antibacterial This requires consideration of antibacterial materials. For scratch resistance, consider hardened materials.

4. Whether there will be problems with the superposition of colors: A common consideration is that multi-color superposition cannot use Screen printing and needs to consider Digital Printing.

5. Consideration of cost: Digital Printing or Silicone Rubber Keypad can be considered as Overlay when the quantity is large.

6. Embossing high design: Button height: 0mm – 1.3mm. The best height of Tactile Feedback for Button Embossing is 0.3-0.5mm. If the height is greater than 0.5mm, Tactile Dot needs to be added above the Metal Dome to increase the product feel.

The height of the LEDs window: 0-0.5mm. It is mainly to prevent the LEDs from breaking the Graphic Overlay

Blind spot height: 0.1-0.7mm. Design to reduce operational errors.

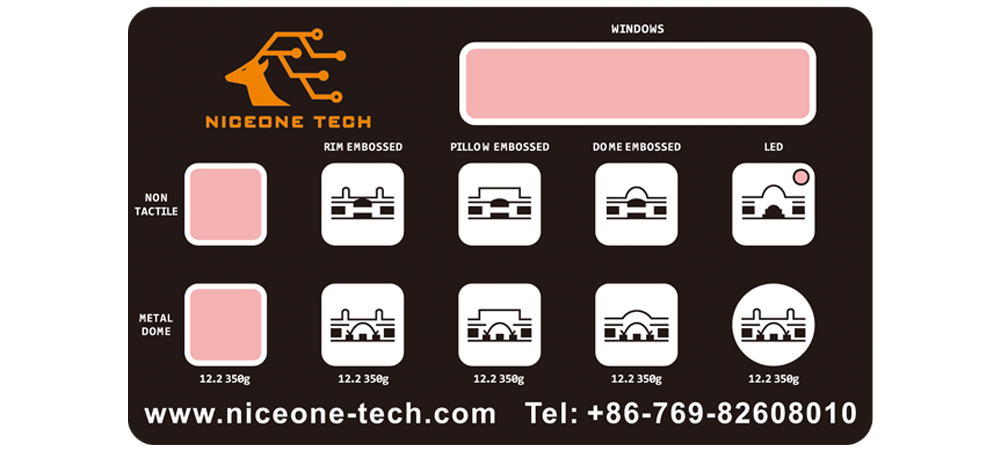

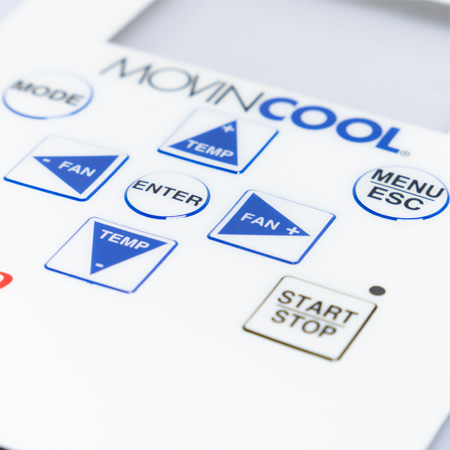

7. The design of the Embossing shape of the Button is as follows:

8. Window back treatment:

For OCA windows, a vacuum is required to remove air bubbles between the window and the PC window. The window is printed with UV points, which can eliminate Newton’s rings. Commonly used for Membrane Switch with a PC window behind the Overlay and a large gap.

9. For the uniform color of Overlay and no other colors, it is recommended to use materials above 0.18, otherwise convex marks will appear.

Layer 2: What does Adhesive need to consider?

The choice of thickness: 0.125-1mm, it is highly recommended to choose 0.175-0.225, so that the Tactile Feedback of the product will be better than the other two.

If it is Non-Tactile, you can choose 0.125mm or even 0.05mm is feasible, and the cost will be reduced.

Metal Dome above 10mm needs to consider shrapnel above 0.225mm, Tactile is better.

For backlight solution and Resin Dome structure, you need to choose 0.5-1mm foam tape.

What are the enhancement designs of Graphic Overlay?

1. Blind spot bumping: Reduce key operation errors.

2. Resin Dome: Makes the product more aesthetic.

3. Plug-in type: reduce mold cost.

4. OCA: The PC window and the panel are attached without bubbles, which is different from the conventional panel printing dots.

5. Metal wire drawing design: More modern aesthetic.

6. Laminate with various backplanes: Reduce customer assembly time and increase product thickness.

7. Digital Printing: Let your products come with gradient colors.

8. Metal color panel design: Use mirror silver or brushed material.

9. Combination with touch screen: The combination of OCA and touch screen often appears in Membrane.

10. The design of Dome Array saves customers’ assembly time.

11. Variable code design.

More design enhancements can be negotiated with Niceone-Keypad to make your Graphic Overlay more competitive.

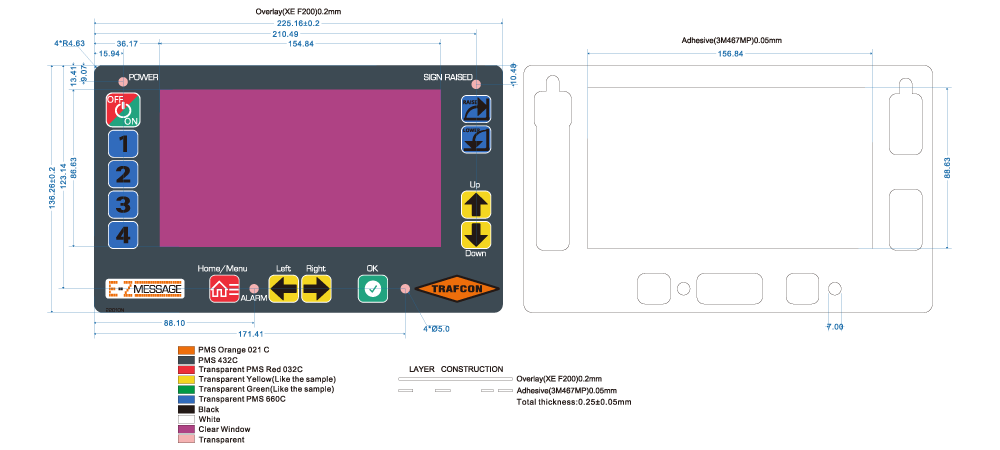

Make a plan suitable for the customer and complete the design drawing for the customer to confirm:

After the customer understands their needs, the choice of product materials, whether to choose high value-added design and cost estimation, we can design the drawings. The time for designing the drawings is generally 1-7 days according to the completeness of the drawings. The best client drawings are presented to the Niceone-Keypad designer with two things:

1. Editable vector graphics.

2. Accurate color coding or customer sample color card.

Production of Graphic Overly:

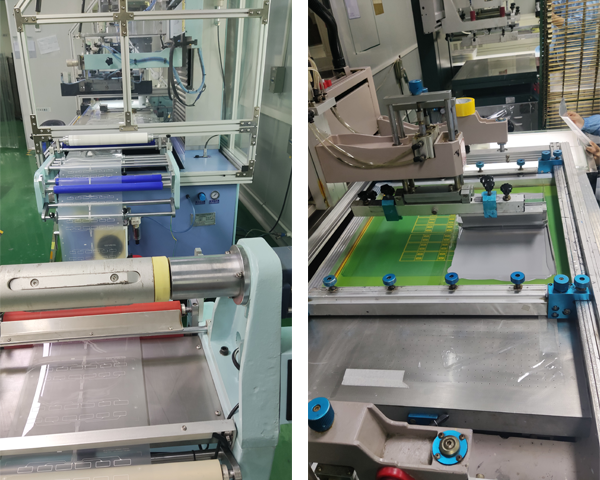

Screen printing process:

Overlay:

1) Squeegee and squeegee installation and adjustment.

2) Check screen and plate registration.

3) Take ink.

4) Trial printing.

5) Check film and sample plate to check whether they meet the special requirements.

6) Printing production.

7) Baking ink.

8) Recycled ink.

9) Cleaning knives and stencils.

Convex process:

Convex after heating the Overlay.

Mounting process:

Surface glue lamination: the punched and convex panel is centered with the surface glue, and the surface line is punched to synthesize the shape after completion.

How to ensure high quality of your Graphic Overlay – Graphic Overlay Detection.

Silkscreen part:

Niceone-Keypad also needs to do (the silver oil line is also tested in strict accordance with the following requirements):

1. Check the film and sample for the printing pattern;

2. Check whether the color meets the requirements of the sample or color number;

3. The printed text and pattern must be clear, without blurring, ghosting, or zigzag;

4. During the printing process, pay attention to blocking nets, foreign objects, oil stains, and scrapers. Marks, sticky nets, inaccurate sets, etc;

5. Ink adhesion inspection.

Stamping part:

1. When punching the pipe position hole, pay attention to the center position of the pipe position hole and do not deviate;

2. Check the embossed product against the sample for deviation, and do relevant tests;

3. Check whether the pipe position hole is out of position;

4. Check whether the convex position of the product after hot pressing is offset, indentation, etc.

Fitting part:

1. Correctly fit the tape according to the template and process;

2. Pay attention to air bubbles, dust, foreign objects, and misalignment when laminating the tape;

3. During the entire lamination process, pay attention to cooperating with the processes of other departments;

4. Whether the correct tape is attached;

5. Check for air bubbles, dust, foreign objects, and misalignment after lamination.

Appearance inspection part:

1. Be careful not to have black spots, nail prints, oil stains, white spots, indentations, etc. on the inspection panel;

2. Check whether the glue is pasted and pasted correctly;

3. If there is a panel with printing oil, pay attention to the surface without oil, dust and other sundries;

4. If there is a panel that is manually punched and hot-pressed, it is necessary to check whether the convex position is offset, etc.;

5. Packaging inspectors should take care not to scratch the panel with their fingers.

Extension

Overlay aspects:

The Overlay of the Membrane Switch needs to be tested 4 times:

A. Before printing, it is necessary to check whether the panel material is selected according to the production document, and perform a 100-grid test to detect the ink adhesion.

B. After printing, it is necessary to check again whether the color number of the color meets the requirements of the drawing, and whether there is trachoma and light transmission.

C. It is necessary to detect whether the ink is peeled and scratched when making bumps.

D. Check whether the Overlay is scratched after placement.

Tactile Feedback aspects:

Tactile Feedback test: The Tactile Feedback test needs to pay attention to the height of the buttons, and select the appropriate load and stroke of Metal.

The selection of molds, the selection of structure and the vent holes all require pre-production evaluation of the project when making drawings to avoid various problems.

QC testing also needs to pay attention to the test of Tactile Feedback, unless it is a Non-Tactile Membrane switch without any feel.

Resin Dome aspects:

Resin keys without any impurities.

Graphic Overlay problems and solutions:

* Does the color need a gradient and too many colors: Digital Printing

* Use environment and storage environment: The main influence is Adhesive, the use environment and storage environment of Membrane Switch made by 3M adhesive can reach -25-80 degrees Celsius, while DT and Nitto tapes are usually 10-80 degrees Celsius and cannot be used at low temperature.

* Newton’s rings appear in Graphic Overlay: Use OCA technology or UV dots to print between the PC window and the Overlay.

* The Graphic Overlay window is scratched: Use hardened polycarbonate material as the panel or window, or EBG material as the Overlay.

* The tactile feedback of Graphic Overlayh is poor: Metal Dome needs to choose a suitable load, and the thickness of Overlay material needs to be 0.125-0.2mm and it needs to be convex. The adhesive layer needs to be adhesive below 0.3mm.

Niceone-Keypad packaging:

1. The thread end can be added with product PN, PO and Date by paper label or pad printing label.

2. The outer box label is convenient for customers to know the quantity and date of each box, and the product can be traced.

3. The use of foam reduces product collision.