Contact

Write to Us And We Would Be Happy to Advise You.

Do you have any questions, or would you like to speak directly with a representative?

By peter

If you are looking to design a tactile switch that has a long lifespan and is reliable, then you may want to consider using a dome switch PCB. Dome switches are a type of tactile switch that are commonly used in keyboards, remote controls, and other electronic devices. They are known for their durability and ability to withstand repeated use.

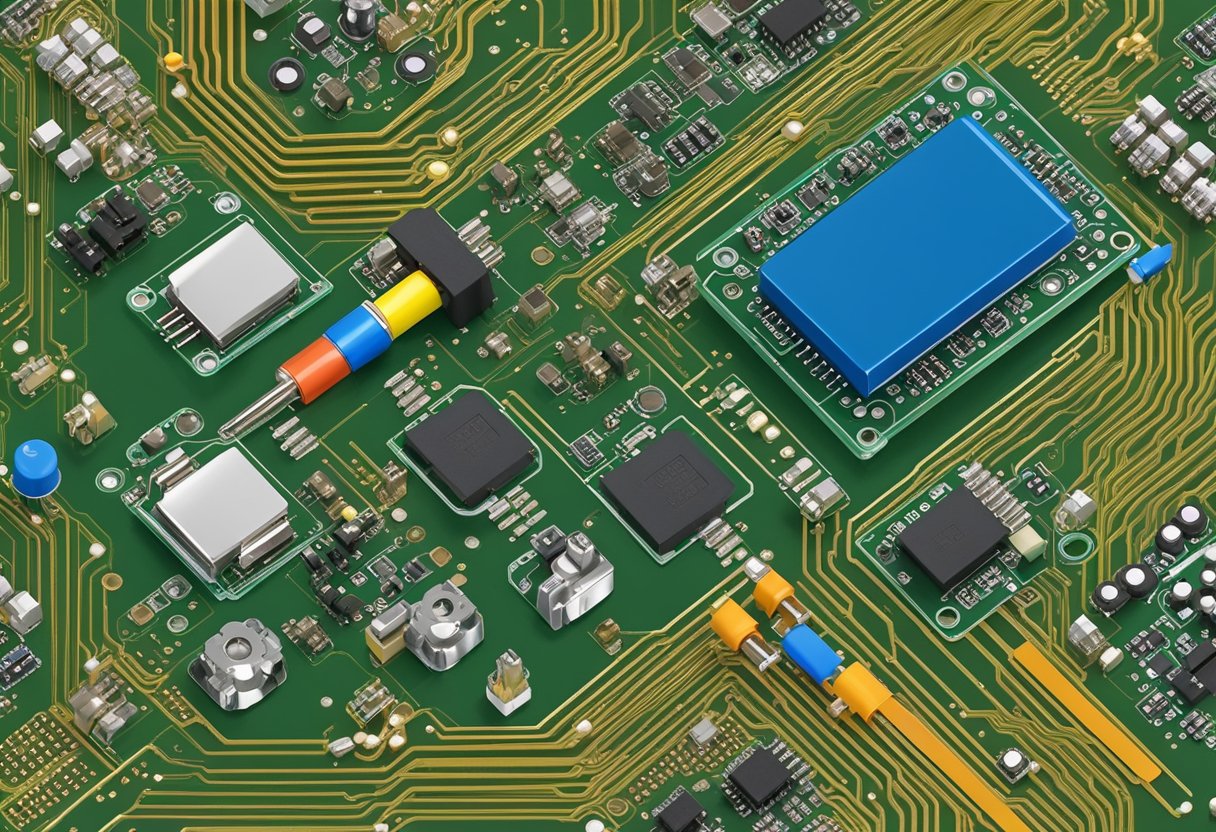

A dome switch PCB is a type of printed circuit board that incorporates dome switches into its design. The switches are made up of a metal dome that is placed on top of a printed circuit board. When the dome is pressed, it collapses and makes contact with the circuit board, completing the electrical circuit. This creates a tactile response that lets the user know that the switch has been activated.

Dome switch PCBs are popular because they are easy to manufacture, have a long lifespan, and are resistant to wear and tear. They are also customizable, allowing for a wide range of shapes and sizes to fit different applications. If you are looking for a reliable and long-lasting switch solution, then a dome switch PCB may be the right choice for you.

Dome switch PCBs are a type of printed circuit board that utilizes dome switches to provide tactile feedback to the user. These switches are made up of a thin metal dome that collapses when pressed, completing an electrical circuit. Dome switches are commonly used in applications where a user needs to be notified that a button has been pressed, such as keyboards, game controllers, and medical devices.

The design of a dome switch PCB involves several key principles. The first is the selection of the appropriate dome switch for the application. Dome switches come in a variety of sizes and actuation forces, and the selection of the appropriate switch is critical to ensure that the user receives the desired tactile feedback. The second principle is the placement of the dome switches on the PCB. The switches must be placed in a way that ensures that they will be activated when the user presses the button, but also that they will not be activated accidentally.

Another important design principle is the selection of the appropriate materials for the PCB. The PCB must be able to withstand the forces applied by the user when pressing the buttons, as well as any environmental factors such as temperature and humidity. The use of high-quality materials is critical to ensure that the PCB will function reliably over its lifetime.

There are several types of dome switches that can be used in dome switch PCBs. The most common type is the metal dome switch, which is made up of a thin metal dome that collapses when pressed. Metal dome switches are known for their durability and reliability, making them a popular choice for many applications.

Another type of dome switch is the polydome switch, which is made up of a flexible polymer dome. Polydome switches are typically less expensive than metal dome switches but may not be as durable or reliable.

In conclusion, the design of a dome switch PCB involves several key principles, including the selection of the appropriate dome switch, the placement of the switches on the PCB, and the selection of high-quality materials. There are several types of dome switches that can be used in dome switch PCBs, each with its own advantages and disadvantages. By understanding these principles and selecting the appropriate components, you can ensure that your dome switch PCB will function reliably over its lifetime.

When manufacturing dome switch PCBs, it is important to select appropriate materials for the job. The materials selected should be able to withstand the forces applied during the switch actuation process. The most commonly used materials for dome switches are stainless steel and nickel silver. Stainless steel is preferred for its high durability, resistance to corrosion, and low cost. Nickel silver, on the other hand, is preferred for its high conductivity and resistance to wear.

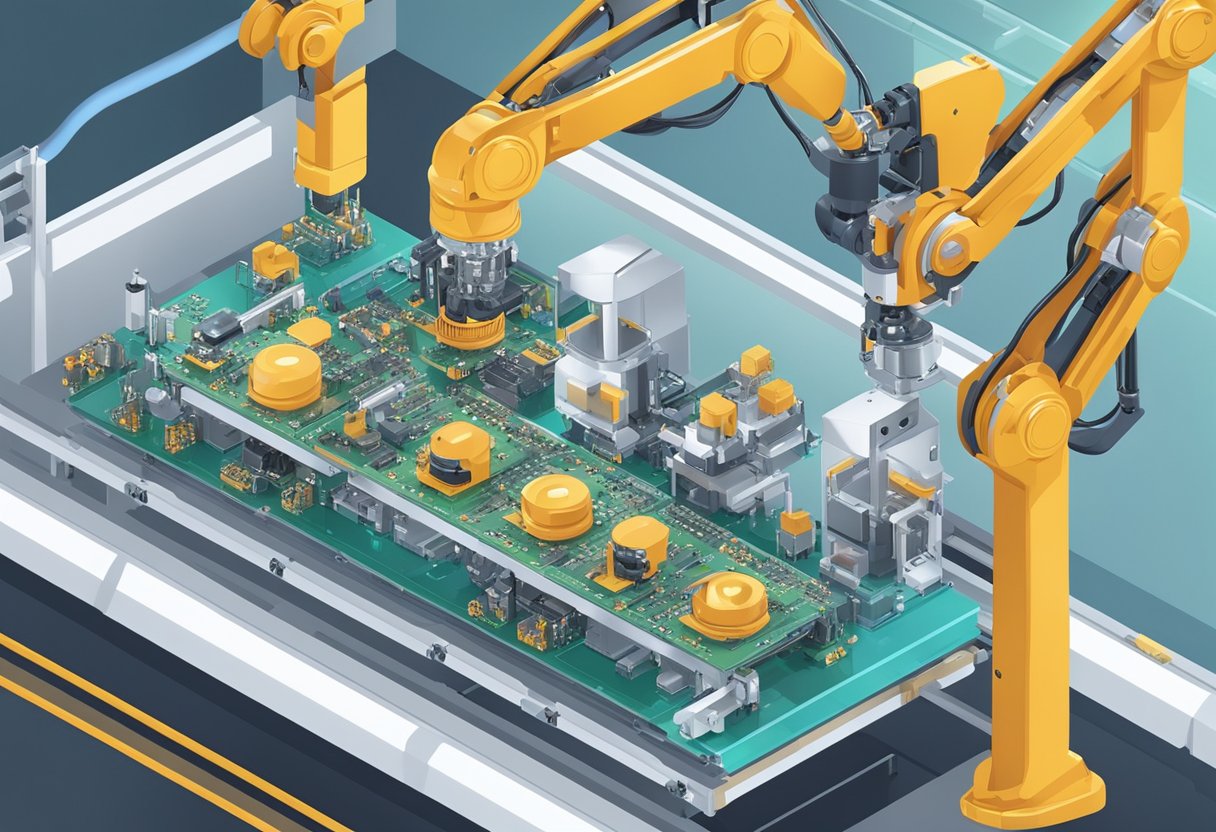

The production of dome switch PCBs involves several techniques. The first step is to design the PCB layout, which includes the placement of the dome switches. The next step is to fabricate the PCB using the selected materials. Once the PCB is fabricated, the dome switches are placed on the PCB using a pick-and-place machine. The switches are then soldered onto the PCB using a reflow oven.

During the manufacturing process, it is important to ensure that the dome switches are placed correctly on the PCB. This is because the performance of the switch is dependent on the location of the dome. The dome should be placed directly over the contact point on the PCB to ensure proper actuation.

In conclusion, the manufacturing process of dome switch PCBs involves careful selection of materials and precise production techniques. By following these steps, you can ensure that your dome switch PCBs are of high quality and will perform reliably over time.

When designing a PCB with dome switches, it’s important to consider compatibility with the electronic devices you plan to use. Here are some compatibility considerations to keep in mind:

When assembling your PCB with dome switches, you have several options to choose from. Here are some common assembly methods:

Overall, when integrating dome switches into your electronic device, it’s important to consider compatibility and assembly methods to ensure a smooth and successful integration.

Dome switch PCBs are known for their excellent electrical properties. They have a low contact resistance, typically between 100mΩ and 200mΩ, and can handle a wide range of currents and voltages. The actuation force required to activate the switch can range from 50g to 500g, depending on the specific switch. When designing your PCB, it’s important to choose a switch with the appropriate actuation force for your application.

Dome switch PCBs are highly durable and can withstand millions of actuations before failure. The lifespan of a switch depends on several factors, including the force required to actuate the switch, the size and shape of the dome, and the materials used in the construction of the switch. Snaptron’s S-Series solder metal dome switches, for example, have a lifespan of up to 1 million cycles, typical, and may vary by application and design.

It’s important to note that the lifespan of a switch can be affected by factors such as the operating environment and the quality of the PCB design. To ensure maximum lifespan, it’s important to choose a switch that is appropriate for your application and to follow best practices for PCB design and assembly.

In summary, dome switch PCBs offer excellent electrical properties and are highly durable, making them an excellent choice for a wide range of applications. When choosing a switch, it’s important to consider factors such as actuation force and lifespan, and to follow best practices for PCB design and assembly to ensure maximum performance and reliability.

Over the years, there have been significant advancements in dome switch technology. One of the latest trends is the integration of metal dome switches with printed circuit boards (PCBs). This integration has led to the development of metal dome PCB switches, which offer a wide range of benefits. For instance, they are more reliable, have a longer lifespan, and are more resistant to wear and tear compared to traditional switches.

Another innovation in dome switch technology is the use of polyimide film. This material is used to create flexible circuits that can be used in a variety of applications. Polyimide film has excellent thermal stability, making it ideal for use in high-temperature environments. It is also highly resistant to chemicals, making it suitable for use in harsh environments.

The future of dome switch technology looks promising. One of the areas that are expected to see significant growth is the use of dome switches in wearable devices. As the demand for wearable technology continues to grow, dome switches are likely to become more popular due to their small size and reliability.

Another area that is expected to see growth is the use of dome switches in the automotive industry. Dome switches are already used in car interiors for functions such as window controls and seat adjustments. However, with the increasing demand for electric vehicles and self-driving cars, dome switches are likely to be used more extensively in the future.

Overall, the future of dome switch technology looks bright, and we can expect to see more innovations and advancements in the coming years.

Do you have any questions, or would you like to speak directly with a representative?