Contact

Write to Us And We Would Be Happy to Advise You.

Do you have any questions, or would you like to speak directly with a representative?

By hqt

In the realm of agriculture equipment, graphic overlays play a vital role in enhancing functionality, safety, and user experience. These overlays provide an intuitive interface for farmers and operators to interact with complex machinery effectively. Standardization and careful consideration of materials are crucial to ensure the durability and longevity of these graphic overlays. In this article, we will delve into the significance of graphic overlays in agriculture equipment, explore the standardization processes involved, and discuss the materials that need to be considered for optimal performance.

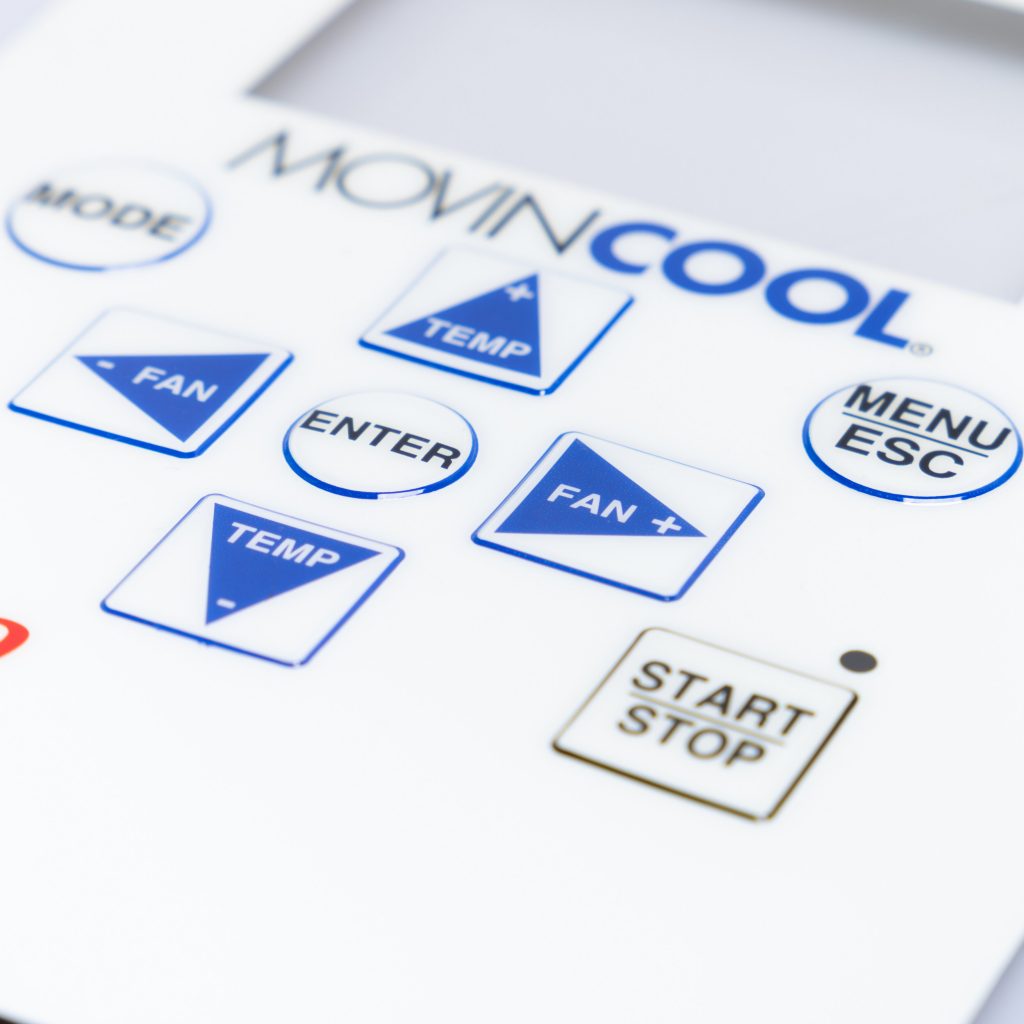

A graphic overlay serves as the primary user interface component of agriculture equipment. It is typically a printed and visually appealing layer that lies on top of the control panel, housing buttons, switches, and other interface elements. These overlays are responsible for conveying essential information, such as operating instructions, safety warnings, and equipment status indicators, to the users.

Graphic overlays play a pivotal role in the agriculture sector by enabling seamless communication between operators and machinery. They provide intuitive controls, allowing users to operate complex equipment efficiently. Moreover, these overlays enhance safety by clearly displaying warning signs and emergency shutdown buttons. The standardization and application of graphic overlays ensure consistent user experiences across different agriculture equipment, regardless of the manufacturer.

Standardization is crucial for graphic overlays to ensure compatibility, usability, and ease of maintenance across various agriculture equipment. Let’s explore some essential aspects of standardization:

Consistent Design and Layout

To achieve standardization, it is essential to establish consistent design and layout guidelines for graphic overlays. This includes using standardized icons, symbols, and text styles to convey information effectively. By following a consistent design language, operators can easily navigate different equipment and perform tasks without confusion.

Ergonomic Considerations

Standardization also involves ergonomic considerations to ensure the comfort and usability of operators. The positioning of buttons, switches, and indicators should be optimized for intuitive operation. Additionally, the size, shape, and tactile feedback of these elements need careful consideration to enhance user experience and prevent accidental inputs.

Durability and Resistance

Graphic overlays in agriculture equipment are exposed to harsh operating conditions, including extreme temperatures, moisture, UV radiation, and chemical exposure. Therefore, standardization requires the selection of durable materials and protective coatings that can withstand these environmental challenges. The overlays must be resistant to fading, discoloration, abrasion, and chemical damage to maintain legibility and functionality over time.

The selection of materials for graphic overlays is crucial to ensure their durability, visual appeal, and resistance to environmental factors. Here are some materials commonly used in agriculture equipment:

1. Polyester (PET)

Polyester is a popular choice for graphic overlays due to its excellent durability and resistance to chemicals, moisture, and UV radiation. It offers high clarity and can withstand harsh environmental conditions without compromising legibility. Moreover, polyester overlays can be printed with vibrant colors and graphics, making them visually appealing.

2. Polycarbonate (PC)

Polycarbonate overlays provide exceptional impact resistance, making them suitable for rugged agriculture environments. They offer excellent clarity, allowing for high-resolution printing of graphics and text. Polycarbonate overlays are known for their dimensional stability, which prevents warping or distortion over time.

3. Acrylic

Acrylic overlays are valued for their optical clarity, making them an ideal choice when visual aesthetics are paramount. They are resistant to yellowing and provide good resistance to abrasion and chemicals. However, compared to polyester and polycarbonate, acrylic overlays may have lower impact resistance.

4. Adhesive and Coating Materials

Apart from the overlay material itself, the selection of adhesive and coating materials is equally important. Adhesive materials should provide strong bonding to the equipment surface, ensuring long-term adhesion even under challenging conditions. Coating materials, such as hard coats or anti-glare coatings, can enhance the durability and visibility of the overlays.

Q1: What are the key considerations for selecting materials for graphic overlays in agriculture equipment?

A1: The key considerations include durability, resistance to environmental factors, visual appeal, and compatibility with the equipment surface. Materials like polyester, polycarbonate, and acrylic are commonly used due to their respective properties.

Q2: How can standardization benefit agriculture equipment manufacturers and operators?

A2: Standardization ensures compatibility, usability, and ease of maintenance across different equipment, regardless of the manufacturer. It allows manufacturers to streamline their production processes and reduces training efforts for operators.

Q3: Can graphic overlays be customized according to specific equipment requirements?

A3: Yes, graphic overlays can be customized to incorporate specific equipment requirements, such as branding, control layout, and specialized instructions. Customization options include color choices, text styles, and the inclusion of company logos.

Q4: Are graphic overlays easy to install and replace?

A4: Yes, graphic overlays are designed for easy installation and replacement. They are often equipped with adhesive backing, allowing operators or maintenance personnel to remove and replace them when necessary.

Q5: Can graphic overlays be used in outdoor agriculture equipment exposed to sunlight?

A5: Yes, graphic overlays can be designed and manufactured to withstand UV radiation from sunlight. Materials like polyester and polycarbonate are known for their UV resistance, ensuring long-lasting performance even in outdoor environments.

Q6: How can graphic overlays improve safety in agriculture equipment?

A6: Graphic overlays play a vital role in enhancing safety by clearly displaying warning signs, emergency shutdown buttons, and safety instructions. They ensure that operators are aware of potential hazards and can take appropriate actions.

Graphic overlays in agriculture equipment are indispensable for efficient operation, safety, and user experience. By adhering to standardization processes and carefully considering materials, manufacturers can produce overlays that withstand harsh environmental conditions while providing clear and intuitive interfaces for operators. The selection of materials such as polyester, polycarbonate, and acrylic, coupled with suitable adhesives and coatings, ensures the durability and longevity of graphic overlays. As agriculture equipment continues to evolve, the standardization and material considerations for graphic overlays will remain crucial in driving productivity and safety.

Do you have any questions, or would you like to speak directly with a representative?