Contact

Write to Us And We Would Be Happy to Advise You.

Do you have any questions, or would you like to speak directly with a representative?

By hqt

Have you ever wondered how those buttons that control your electronic devices and appliances work? If you have, then you’ve come to the right place! Today, we’re going to unlock the mysteries of how membrane switches work and explore the advantages and customization options available for them.

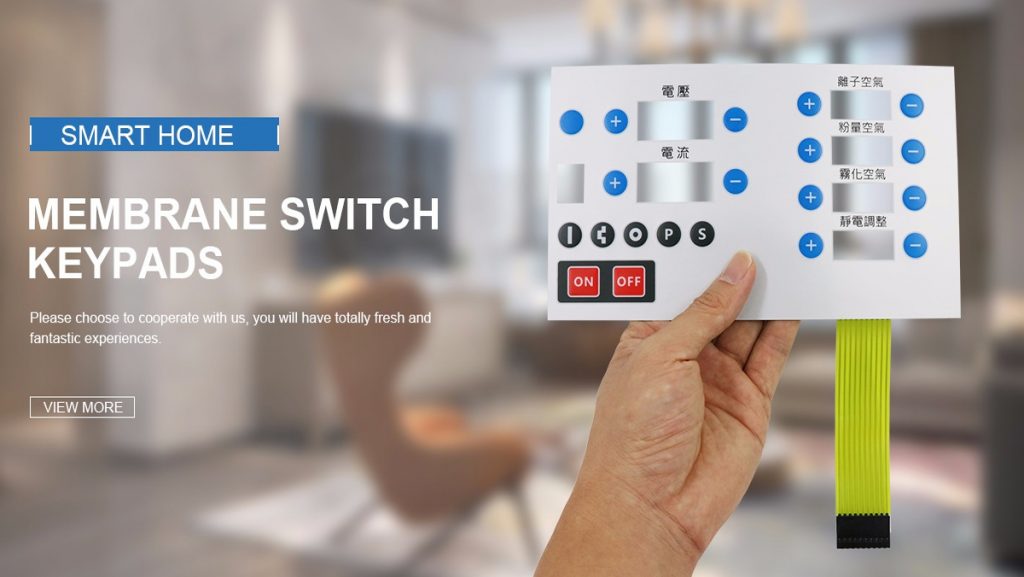

Membrane switches are a type of electrical switches that are used to control the functioning of electronic devices and appliances. They are made up of several layers of materials, such as plastic, rubber, and metal, and are used in a wide range of applications including consumer products, medical equipment, and industrial control systems. In this blog, we’ll learn about how do membrane switches work and their different components, advantages, types, and customization options.

Membrane switches are flexible electrical switches that are made up of several layers of materials, such as plastic, rubber, and metal. They are usually flat, but can be curved to fit the shape of the device they’re controlling. They are usually used to control the functioning of electronic devices and appliances, such as televisions, sound systems, and other consumer products. They can also be used for medical equipment, industrial control systems and other devices.

Membrane switches are generally easier to use and require less force to activate than traditional electrical switches, such as push buttons. They are also more reliable and durable, making them a great choice for applications that require long-term use. Additionally, membrane switches are typically much thinner than traditional mechanical switches, making them ideal for applications where space is limited.

Membrane switches work by sending an electrical signal to the device they’re controlling when they’re activated. When the switch is activated, a contact between two layers of the membrane switch closes, which causes an electrical signal to be sent to the device. This signal can then be used to control the device’s functions.

The contact between the two layers of the membrane switch is usually made of metal and is coated with a conductive material. When the switch is activated, the contact is closed and an electrical signal is sent to the device. The signal can then be used to control the device’s functions.

Membrane switches are made up of several different components that work together to create the switch. The main components of a membrane switch are the base layer, the overlay, the contact layer, and the actuator.

The base layer is the bottom layer of the membrane switch and is usually made of polyester or polycarbonate. It can also be made of other materials such as polyethylene or polypropylene. This layer provides the structural support for the switch and ensures that the other components are securely held in place.

The overlay is the top layer of the membrane switch and is usually made of polyester or polycarbonate. It is typically printed with the text and graphics that are used to identify the switch and provide instructions on how to use it.

The contact layer is the middle layer of the membrane switch and is usually made of metal. It is coated with a conductive material, such as silver or gold, which allows the contact to close when the switch is activated.

The actuator is the component of the membrane switch that is used to activate the switch. It is usually a metal or plastic dome that is pressed down to close the contact and send the electrical signal to the device.

Membrane switches offer several advantages over traditional mechanical switches. They are typically much thinner than traditional switches, making them ideal for applications where space is limited. They are also easier to use and require less force to activate than traditional switches.

Additionally, membrane switches are generally more reliable and durable than traditional switches. This makes them a great choice for applications that require long-term use. They are also much more resistant to dust, moisture, and other environmental factors, making them ideal for outdoor applications.

There are several different types of membrane switches available. The most common types of membrane switches include tactile switches, non-tactile switches, and capacitive switches.

Tactile switches are the most common type of membrane switch. They are activated by pressing down on a metal or plastic dome, which closes the contact and sends the electrical signal to the device. They are typically used in applications where the user needs to be able to feel when the switch has been activated.

Non-tactile switches are similar to tactile switches but do not require the user to press down on a metal or plastic dome. Instead, they are activated by a capacitive or optical sensor, which can detect the presence of a finger or other object and close the contact.

Capacitive switches are the newest type of membrane switch and are typically used in applications where the user needs to be able to touch the switch without pressing down on it. They are activated by a capacitive sensor, which can detect the presence of a finger or other object and close the contact.

Membrane switches can be customized to meet the specific needs of your application. The overlay can be printed with custom text and graphics, and the contact layer can be made from a variety of materials. Additionally, membrane switches can be designed with special features such as LED lights, tactile feedback, and anti-microbial coatings.

When designing a membrane switch, there are several important considerations that must be taken into account. The most important consideration is the environment in which the switch will be used. It is important to ensure that the materials used in the switch are suitable for the environment they will be used in. Additionally, the switch should be designed to withstand the forces that will be applied to it, such as pressure and vibration.

Another important consideration is the size and shape of the switch. It is important to ensure that the switch is large enough to be easily activated by the user. Additionally, the switch should be designed to fit the shape of the device it is controlling.

Finally, the switch should be designed to meet the specific needs of the application. For example, if the switch is being used in an application where the user needs to be able to feel when the switch has been activated, then a tactile switch should be used.

Quality control is an important part of the membrane switch manufacturing process. It is important to ensure that the switch meets the design requirements and performs its function properly. To ensure the highest quality switches, manufacturers typically use automated testing equipment that can identify any potential defects.

Additionally, manufacturers typically use quality control processes such as incoming material inspection, final product testing, and process validation to ensure that the switches meet their specifications. These processes help to ensure that the switches are of the highest quality and perform their functions properly.

Membrane switches are an important component of many electronic devices and appliances. They are made up of several layers of materials, such as plastic, rubber, and metal, and are used to control the functioning of the device. They are generally easier to use and require less force to activate than traditional electrical switches, making them a great choice for applications that require long-term use. Additionally, membrane switches can be customized to meet the specific needs of your application and are subject to quality control processes to ensure that they meet their specifications.

If you’re looking for a reliable and durable switch for your electronic device or appliance, then membrane switches are a great choice. Now that you know how do membrane switches work, you can make an informed decision on which type of switch is right for your application.

Do you have any questions, or would you like to speak directly with a representative?