Contact

Write to Us And We Would Be Happy to Advise You.

Do you have any questions, or would you like to speak directly with a representative?

By hqt

A PCB membrane switch is a technologically advanced device that plays a crucial role in various electronic systems. These switches are highly efficient, enabling seamless communication between human input and electronic devices. The primary keyword, PCB membrane switch, refers to the combination of a printed circuit board (PCB) as the main structural component, and a membrane switch as the control interface. This powerful combination offers numerous benefits, including durability, reliability, and customization options.

The foundation of a PCB membrane switch lies in its construction. The PCB is typically made from a copper-clad cloth or fiber infused into a resin material. This combination of cloth and resin creates a specific cloth-to-resin ratio, determining the laminate’s type designation (e.g., FR-4, CEM-1, G-10, etc.). FR-4 is the most common material used today.

An acid-resistant solder mask is applied to the copper-clad PCB, and the exposed areas that are not covered by the solder mask are etched away using acid. The remaining copper pathways are plated with various metals to protect the copper from corrosion. Gold plating is often required on many PCBs in critical applications where corrosion and exposure to chemicals is an issue.

The PCB membrane switch construction utilizes the PCB as the main structure and support substrate, with the membrane switch on the front of the PCB assembly and the display, along with other discrete components, on the back side of the PCB. This arrangement ensures a compact and efficient design.

A variety of discrete components can be integrated into a PCB membrane switch, including, but not limited to, LEDs, resistors, connectors (both SMT and through-hole), LCD and LED displays, sensors, and speakers. The addition of a daughter board can add even more design flexibility, allowing for direct connections to the PCB membrane switch.

There are several advantages to using a PCB membrane switch in electronic devices, which include:

PCB membrane switches are designed to withstand harsh environmental conditions, including exposure to chemicals and extreme temperatures. This makes them ideal for use in industries such as automotive, aerospace, and medical applications.

The use of a PCB as the primary support structure ensures that the membrane switch is stable and reliable, reducing the risk of malfunctions in critical systems.

PCB membrane switches can be easily tailored to meet specific design requirements and functionality needs, making them highly adaptable to a wide range of applications.

The compact design of a PCB membrane switch allows for easy integration into devices with limited space, making them an excellent choice for small and complex electronic systems.

PCB membrane switches find applications in various industries, such as:

In the medical industry, PCB membrane switches are used in devices like patient monitoring systems, diagnostic equipment, and medical imaging systems, where reliability and precision are crucial.

PCB membrane switches are an integral part of various industrial equipment, such as control panels, automation systems, and manufacturing machinery, where durability and customization play a significant role.

In aerospace and automotive applications, PCB membrane switches are used in control systems, cockpit interfaces, and vehicle dashboards, where they must withstand extreme environmental conditions.

PCB membrane switches are commonly found in consumer electronics like remote controls, home appliances, and gaming devices, where they provide an efficient and user-friendly interface.

When designing a PCB membrane switch, there are several factors to consider, including:

Choosing the right material for the PCB and membrane switch is crucial for achieving optimal performance. FR-4 is the most common material used for PCBs, while materials like polyester and polycarbonate are popular choices for membrane switches.

The circuit design of a PCB membrane switch plays a critical role in ensuring proper functionality. Designers must consider factors such as trace width, spacing, and routing to ensure reliable performance.

Integrating discrete components like LEDs, resistors, and connectors into the PCB membrane switch requires careful planning and design to ensure compatibility and efficient operation.

Designers must consider the environmental conditions in which the PCB membrane switch will be used, such as temperature, humidity, and exposure to chemicals, to select the appropriate materials and design features.

The user interface of a PCB membrane switch must be designed with usability in mind, considering factors such as tactile feedback, labeling, and ease of use.

The production of PCB membrane switches involves several manufacturing processes, including:

The first step in manufacturing a PCB membrane switch is fabricating the PCB itself. This involves creating the copper-clad laminate, applying the solder mask, and etching the copper pathways.

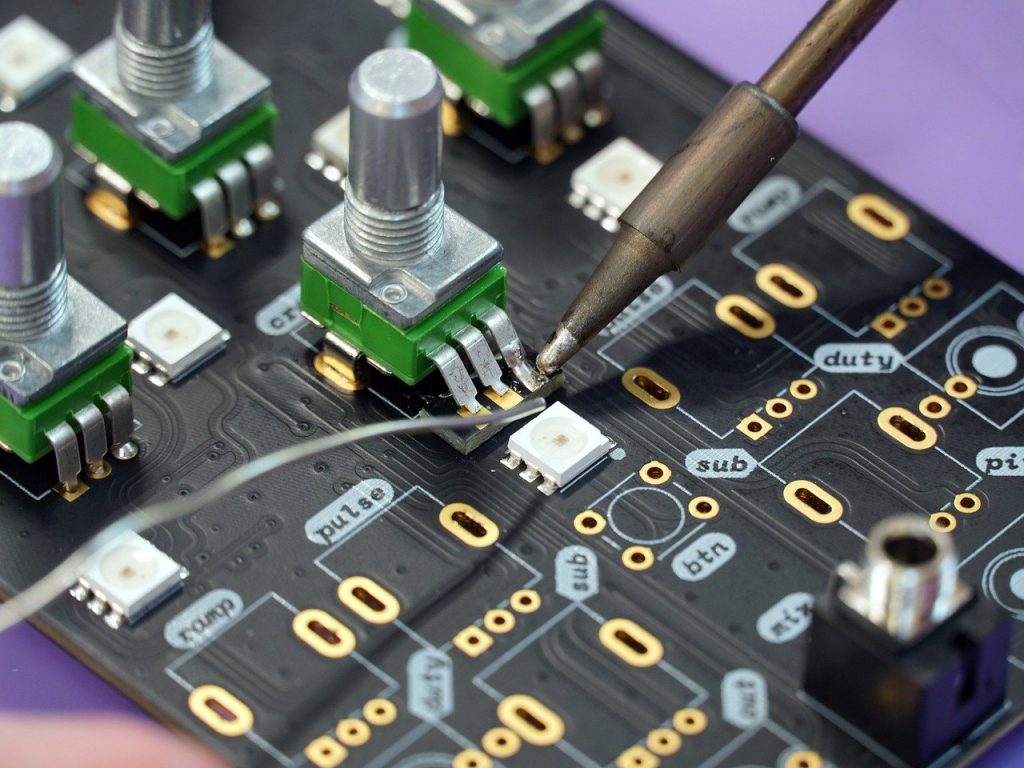

Once the PCB is fabricated, the discrete components, such as LEDs, resistors, and connectors, are assembled onto the board using surface-mount technology (SMT) or through-hole techniques.

After the PCB and discrete components are assembled, the membrane switch is integrated onto the front of the PCB assembly, forming the complete PCB membrane switch.

Before a PCB membrane switch is shipped, it must undergo thorough testing and quality control measures to ensure proper functionality and reliability.

In summary, a PCB membrane switch serves as a versatile and efficient solution for various electronic systems. Its robust construction, customization options, and ability to withstand harsh environmental conditions make it an ideal choice for a wide range of applications. By considering factors like material selection, circuit design, and user interface, designers can create a PCB membrane switch that meets the specific needs of any electronic device. As technology continues to evolve, so too will the capabilities and applications of PCB membrane switches.

Do you have any questions, or would you like to speak directly with a representative?