Contact

Write to Us And We Would Be Happy to Advise You.

Do you have any questions, or would you like to speak directly with a representative?

By hqt

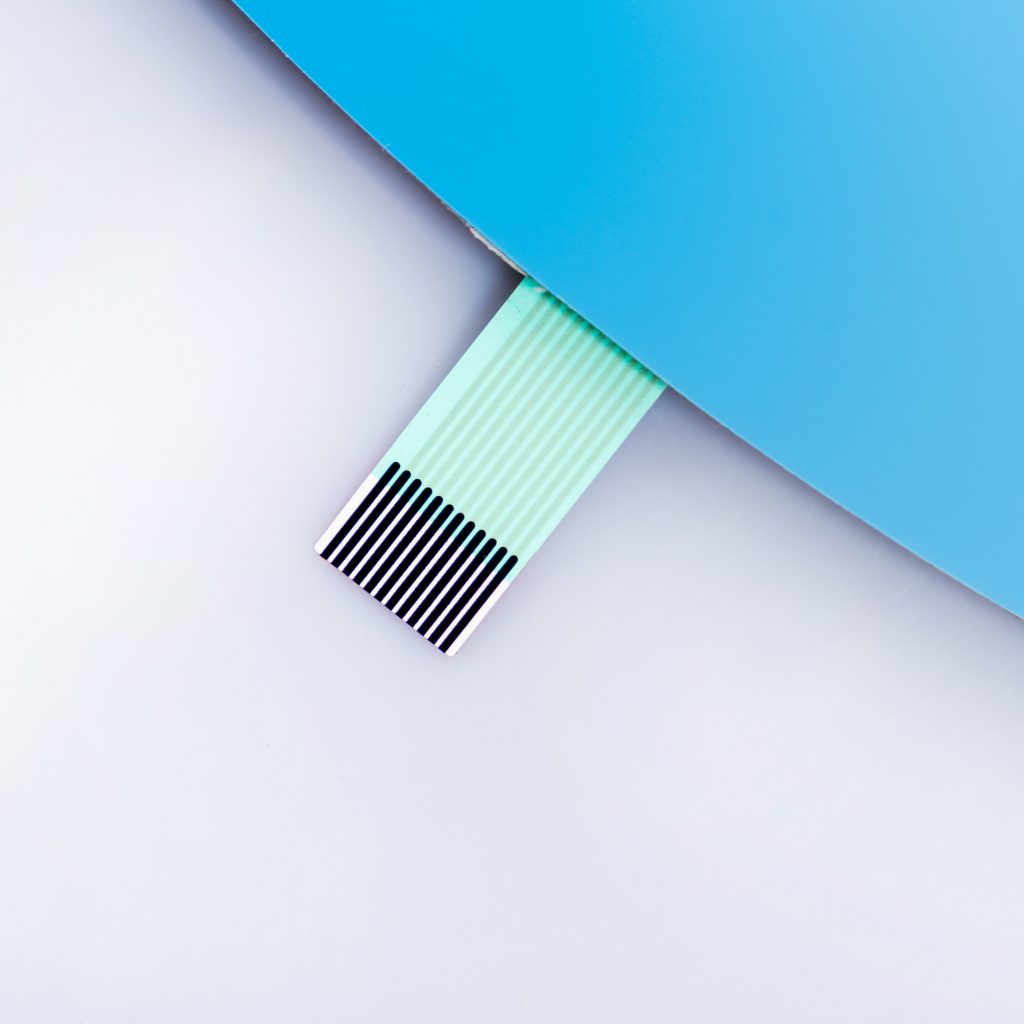

In the world of electronics and technology, membrane switches have become an indispensable component for various devices, from microwave ovens to medical equipment. These thin, flexible switches provide a user interface that is both reliable and efficient. One crucial aspect of manufacturing membrane switches is the silkscreen printing process, which plays a pivotal role in ensuring the functionality and aesthetics of these switches. In this article, we will delve into the intricate world of silkscreen printing of membrane switches, exploring the indicators of quality and the common issues faced during the manufacturing process.

Before we dive into the details of silkscreen printing, let’s take a moment to understand what membrane switches are and why they are essential. Membrane switches are thin, flat electrical switches with a user interface, typically consisting of multiple layers of flexible materials. These switches are known for their durability, ease of use, and cost-effectiveness, making them a preferred choice for various industries.

Silkscreen printing is a critical step in the production of membrane switches. It involves transferring ink onto the surface of the switch using a mesh screen, creating the required patterns, symbols, and text. This printing process serves several crucial functions:

Now that we have a basic understanding of the role of silkscreen printing, let’s explore the indicators that define high-quality printing in the context of membrane switches:

While achieving high-quality silkscreen printing is the goal, there are several common issues that manufacturers may encounter during the process:

In conclusion, silkscreen printing plays a pivotal role in the production of membrane switches, enhancing both their functionality and visual appeal. Manufacturers must pay close attention to indicators of quality such as sharpness, color accuracy, adhesion, and registration accuracy while being vigilant about common issues like ink bleeding, poor adhesion, registration errors, and color inconsistencies. By addressing these factors, manufacturers can ensure the production of reliable and aesthetically pleasing membrane switches.

What are membrane switches used for?

What is the primary advantage of silkscreen printing for membrane switches?

How can manufacturers prevent ink bleeding during the printing process?

What should be done to address color inconsistencies in printed membrane switches?

Do you have any questions, or would you like to speak directly with a representative?