Contact

Write to Us And We Would Be Happy to Advise You.

Do you have any questions, or would you like to speak directly with a representative?

By peter

If you’ve ever used a keyboard, remote control, or any other device with buttons, you’ve likely encountered tactile dome switches. These small, circular switches are commonly used in electronics to provide a tactile response when pressed. They offer a variety of benefits, including durability, reliability, and ease of use.

Tactile dome switches are also known as snap dome switches, because they use a small metal dome to make contact when pressed. This dome is typically made of stainless steel or other metals, and is coated with a conductive material like gold or silver. When the dome is pressed, it collapses and makes contact with a circuit board or other electrical component, completing the circuit and registering the button press.

Because of their small size and simple design, tactile dome switches are ideal for use in a wide range of electronic devices. They can be found in everything from TV remotes to medical equipment, and are often used in applications where reliability and durability are key. With their long lifespan and ease of use, tactile dome switches are an important part of modern electronics design.

Tactile dome switches are a type of momentary switch that are used in a wide variety of electronic devices, including remote controls, keyboards, and game controllers. They are known for their tactile feedback, which provides a satisfying sensation when the switch is pressed.

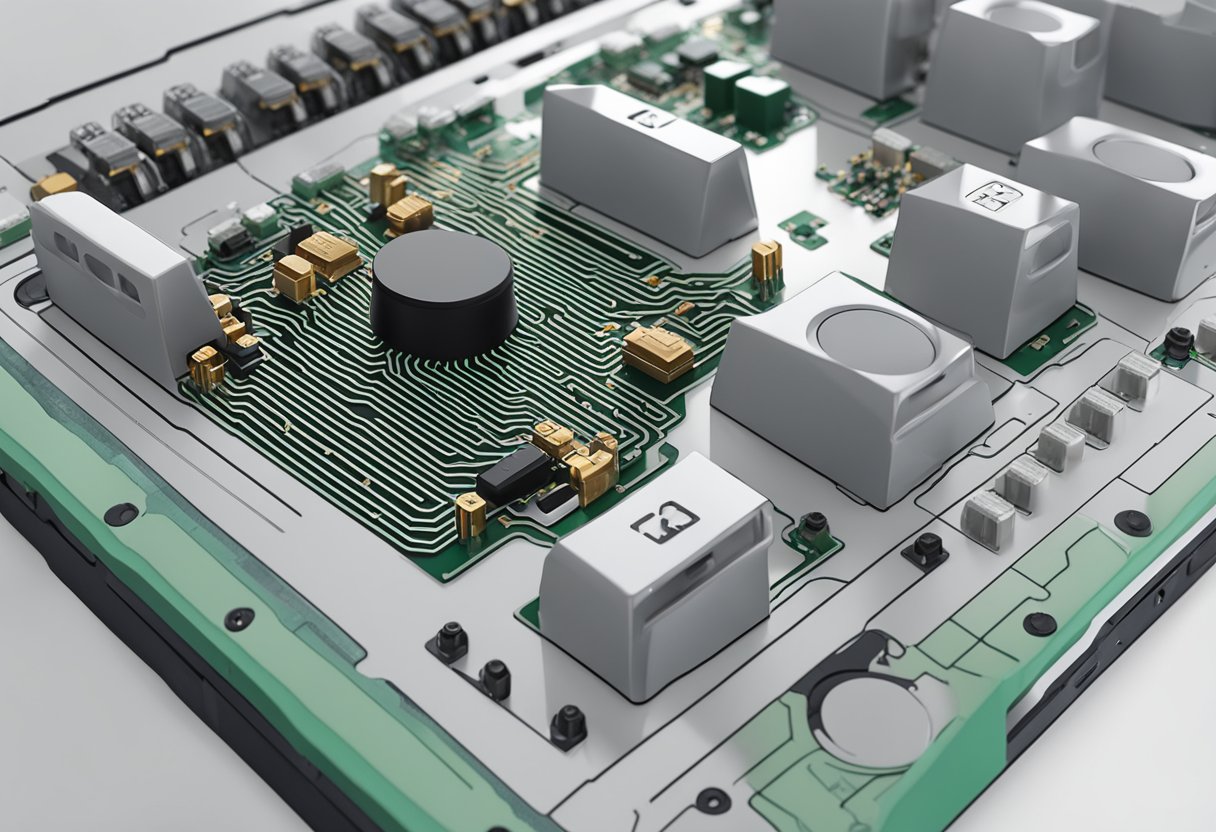

These switches consist of a metal dome that is placed on top of a printed circuit board (PCB). When the dome is pressed, it collapses and makes contact with the PCB, completing the circuit and sending a signal to the device. The dome then returns to its original shape, ready for the next press.

Tactile dome switches come in a range of shapes and sizes, and can be made from different materials such as stainless steel or nickel-plated phosphor bronze. They can also be coated with different materials such as gold or silver to improve their electrical properties.

One of the key advantages of tactile dome switches is their long lifespan. They can typically withstand millions of cycles, making them a reliable choice for devices that are used frequently. They also have a low profile, which makes them suitable for devices with limited space.

Overall, tactile dome switches are a versatile and reliable component that are used in a wide range of electronic devices. They provide a satisfying tactile feedback and have a long lifespan, making them a popular choice for manufacturers.

When it comes to tactile dome switches, there are several mechanical properties that are important to consider. Here are some of the key factors to keep in mind:

Actuation force refers to the amount of pressure required to activate the switch. Tactile dome switches typically have a low actuation force, which means that they can be activated with a light touch. This can be beneficial for users who need to type or input data quickly and efficiently.

Tactile feedback is the sensation that the switch provides when it is activated. Tactile dome switches are known for their crisp, responsive feedback. When the switch is pressed, the metal dome collapses and then quickly returns to its original shape, providing a satisfying tactile sensation. This feedback can be important for users who need to know that their input has been registered.

Durability is a key consideration for any switch, and tactile dome switches are no exception. These switches are known for their long lifespan, with some models rated for millions of cycles. This durability can be important for applications where the switch will be used frequently or in harsh environments.

Overall, tactile dome switches offer a number of mechanical advantages that make them a popular choice for a wide range of applications. Whether you need a switch for a keyboard, a control panel, or another type of device, tactile dome switches are a reliable and efficient choice.

The stem design of tactile dome switches is crucial for their functionality. It is the part of the switch that connects the dome to the printed circuit board (PCB). The stem design determines the amount of force required to activate the switch and the distance the dome needs to travel before it makes contact with the PCB.

The stem design can be either a single leg or a double leg. The single leg stem design is simpler and more cost-effective, but it requires a larger amount of force to activate the switch. The double leg stem design, on the other hand, requires less force to activate the switch, but it is more complex and expensive to manufacture.

The material used to manufacture the dome is also important for the functionality of the tactile dome switch. The most commonly used materials for dome manufacturing are stainless steel and nickel silver.

Stainless steel domes are more durable and have a longer lifespan than nickel silver domes. They are also more resistant to corrosion and wear and tear. However, they require a higher amount of force to activate the switch.

Nickel silver domes, on the other hand, require less force to activate the switch, but they are less durable and have a shorter lifespan than stainless steel domes. They are also more prone to corrosion and wear and tear.

In conclusion, the stem design and dome material are important factors to consider when designing a tactile dome switch. The choice of stem design and dome material depends on the specific requirements of the application.

Tactile dome switches are widely used in various electronic devices and equipment. They provide a reliable and responsive switching mechanism, making them ideal for applications where precise control is required. Here are some common applications and uses of tactile dome switches.

Tactile dome switches are commonly used in computer keyboards. They provide a tactile feedback when pressed, allowing users to type more accurately and efficiently. The switches are usually arranged in a matrix pattern, with each switch corresponding to a specific character or function. Some keyboards also have backlighting to make it easier to see the keys in low-light conditions.

Tactile dome switches are also used in control panels for industrial equipment and machinery. The switches provide a tactile feedback when pressed, allowing operators to control the equipment more accurately and safely. The switches are usually arranged in a logical pattern, with each switch corresponding to a specific function or control. Some control panels also have LED indicators to show the status of the equipment.

In addition to these applications, tactile dome switches are also used in a wide range of other electronic devices, including remote controls, game controllers, and medical equipment. They are also used in automotive and aerospace applications, where reliability and durability are essential.

Overall, tactile dome switches are a versatile and reliable switching mechanism that can be used in a wide range of applications. They provide a tactile feedback that makes it easier to control electronic devices and equipment, and they are designed to withstand harsh environments and heavy use.

When selecting a tactile switch, there are several options available, including linear switches, clicky switches, and tactile dome switches. Each type of switch has its own unique benefits and drawbacks. In this section, we’ll compare tactile dome switches to linear and clicky switches.

Linear switches have a smooth, consistent feel when pressed, with no tactile feedback. They are often used in applications where a user needs to input a large amount of data quickly, such as in gaming or typing. However, because they lack tactile feedback, it can be difficult to tell when the switch has been actuated.

In contrast, tactile dome switches provide a distinct tactile feedback when pressed, allowing the user to know when the switch has been actuated. This makes them ideal for applications where precision and accuracy are important, such as in medical equipment or industrial control panels.

Clicky switches, as the name suggests, produce an audible “click” when pressed. This can be useful in applications where the user needs to know when the switch has been actuated, such as in a keyboard. However, the clicking sound can be distracting in quiet environments, and the tactile feedback can be less precise than that of a tactile dome switch.

Tactile dome switches provide a similar tactile feedback to clicky switches, without the distracting clicking sound. This makes them ideal for applications where a tactile response is needed, but an audible click is not desired.

In summary, tactile dome switches provide a reliable and precise tactile feedback when pressed, making them ideal for a wide range of applications. They offer distinct advantages over linear switches and clicky switches, depending on the specific needs of the application.

Do you have any questions, or would you like to speak directly with a representative?