Contact

Write to Us And We Would Be Happy to Advise You.

Do you have any questions, or would you like to speak directly with a representative?

By hqt

In the world of oil well drilling, precision and control are paramount. The equipment used in this industry must withstand harsh conditions while delivering accurate results. One crucial component in drilling control panels is the membrane switch. These switches play a vital role in ensuring the safe and efficient operation of drilling equipment. In this article, we will delve into the essential factors that demand attention when designing membrane switches for oil well drilling control panels.

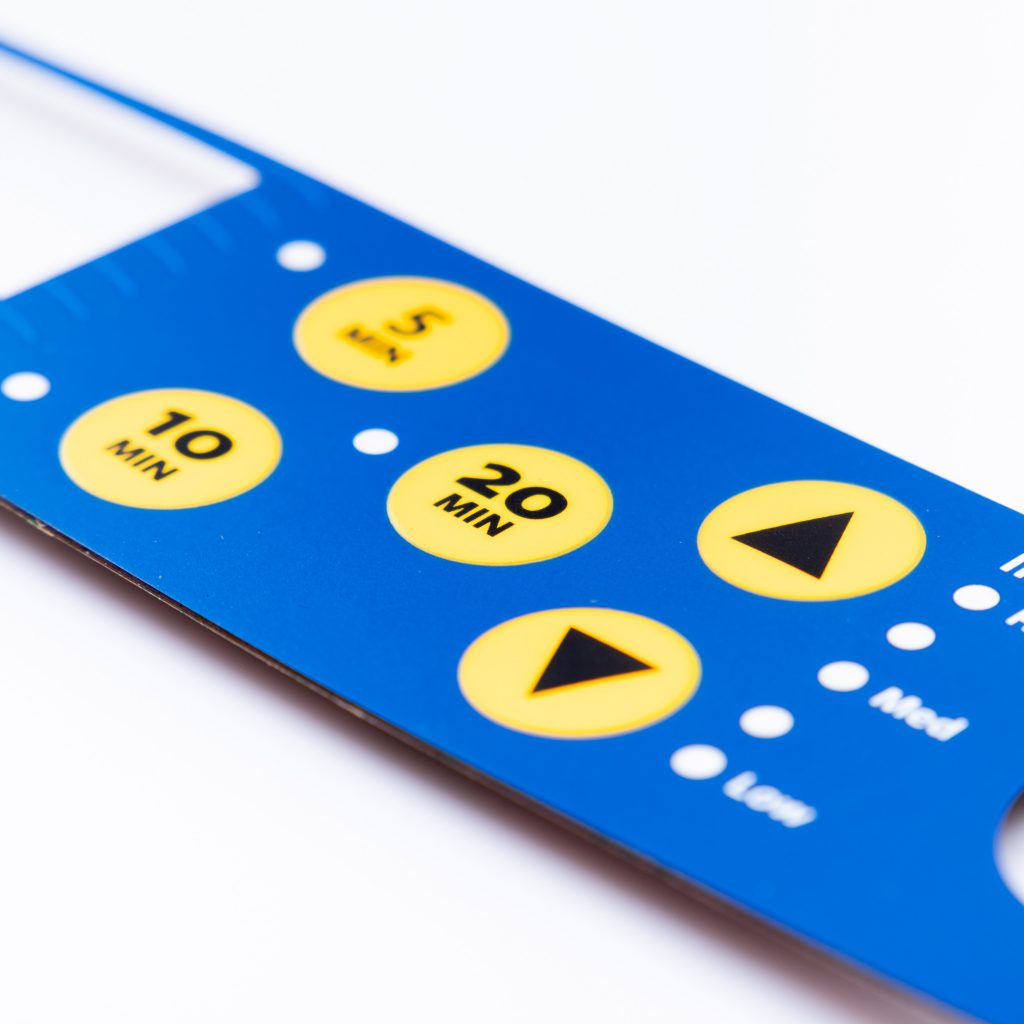

Before diving into the design considerations, let’s grasp the fundamentals of membrane switches. These switches consist of several layers, including a graphic overlay, adhesive spacer, and a circuit layer. When pressure is applied to the graphic overlay, it compresses the spacer, causing a connection to be made within the circuit layer. This simple yet effective mechanism is used in various control panels, including those in the oil drilling industry.

Membrane switches in oil well drilling control panels must be built to last in rugged environments.

Designing an intuitive interface for operators is crucial for efficiency and safety.

Providing tactile feedback enhances the user experience and prevents errors.

The ability to customize membrane switches is essential for specific drilling operations.

Reliable membrane switches are critical to avoid downtime in drilling operations.

Seamless integration with control systems is vital for real-time monitoring and adjustments.

Easy maintenance can reduce downtime and operational costs.

Safety is paramount in oil drilling, and membrane switches must contribute to it.

Balancing quality with cost is essential in any industry, including oil drilling.

Ensure that membrane switches adhere to industry-specific regulations and standards.

Anticipate technological advancements and design switches with adaptability in mind.

As we conclude our exploration of membrane switch design for oil well drilling control panels, it’s evident that attention to detail is crucial. These switches are the interface between human operators and sophisticated machinery, and their design directly impacts safety, efficiency, and productivity in the field.

In this fast-paced industry, where technology and safety standards continually evolve, making informed choices in membrane switch design is imperative. By focusing on durability, user-friendliness, reliability, and compliance, oil drilling companies can ensure that their control panels perform optimally, contributing to the overall success of drilling operations.

1. What is the typical lifespan of membrane switches in oil well drilling control panels?

2. How can I ensure that my membrane switches comply with industry regulations?

3. Are there alternatives to membrane switches for drilling control panels?

4. Can I retrofit my existing control panels with new membrane switches?

5. What benefits do tactile feedback and auditory feedback provide in membrane switches?

Do you have any questions, or would you like to speak directly with a representative?