Contact

Write to Us And We Would Be Happy to Advise You.

Do you have any questions, or would you like to speak directly with a representative?

By hqt

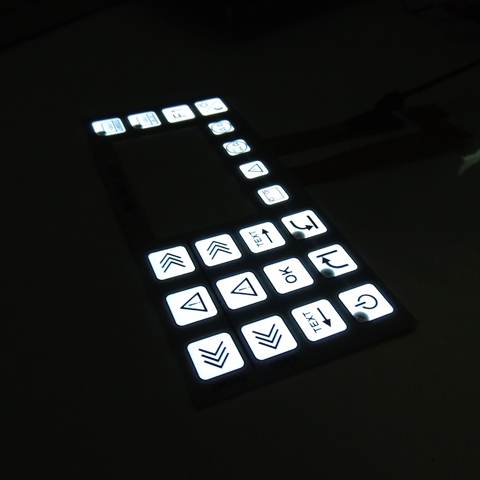

Backlit Membrane Switch is the latest technology of Membrane Switch in recent years. Backlight Membrane Switch works very well in low-light or dark places. But how to design to make your Backlight Membrane Switch backlight better? The engineering team of Niceone-Keypad gave 8 tips.

LGF will make the Backlight Membrane Switch more perfect and outstanding under the control of these 3 points. LGF is also one of the core of Backlit Membrane

For the LGF at the bottom of the button, you can choose a thinner polycarbonate or a polyester below 0.25mm. Too thick LGF material will cause poor tactile feedback

LGF can choose thicker Polycarbonate instead of Polyester at the bottom of the logo or graphic. Because the thickness of Polycarbonate is thicker, the light transmission rate is better. At the same time, there is no need to consider the feel.

Niceone-Keypad usually chooses white instead of transparent color for light guide point ink, because the light guide rate of white will be better. And the ink can choose Mero brand.

The arrangement of light guide points: According to the actual light-emitting requirements and the source of the light source, the arrangement of different light guide points can be adjusted to achieve the most ideal light guide effect. For details, please consult Niceone-Keypad, we can design a drawing for you free of charge.

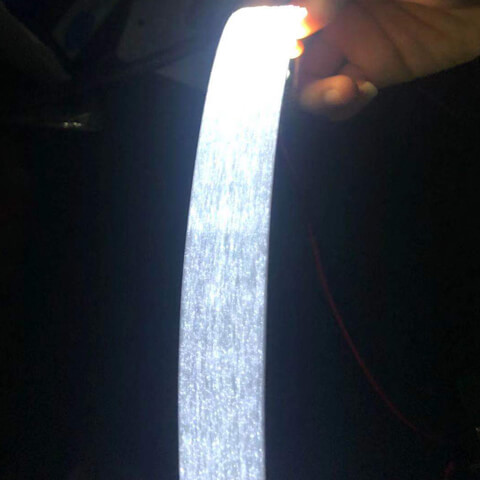

The optical fiber type and EL cold light film type need to pay attention to these two aspects to maximize the effect of Backlit Membrane Switch.

2. Optical fiber: you need to choose a material with good light transmission rate and a plastic shell to wrap the optical fiber cable, you can contact Niceone-Keypad, we can provide free samples for your reference.

3. EL cold light film: mainly material, voltage and inverter selection will affect the brightness.

4. Adhesive: The main function is to keep the light source from being exposed so as to increase the efficiency of repeated transmission of light inside. Therefore, Adhesive needs to choose black adhesive tape as the main choice. Such as 3M9448AB.

5. Sheet selection: white sheet or black do not choose transparent color to prevent light leakage.

6. The light-emitting area of the Backlight Membrane Switch, that is, the transparent color of the panel, try not to choose transparent black: Due to the small particles in the printing ink and the poor light transmittance of the color black, even if the LEDs with higher MCD are selected, the Backlight Membrane Switch effect cannot be perfectly displayed. The best choice is light colors such as white, pink, purple and so on.

7. Line material selection: opaque white PET line or white FPC line should be selected, which is conducive to light reflection.

8. The choice of LEDs: the higher the MCD, the better. At the same time, in order to ensure the feel of the product, the size of the lamp needs to be below 1.2mm. Generally speaking, white LEDs have the most ideal effect.

Niceone-Keypad has been trying to reduce the light transmittance and particles of the transparent black ink during this period. Although we have failed many times, we have been trying again. Fortunately, transparent black has better light transmittance under red and green LEDs. The ink particles have gradually become smaller due to advances in ink technology. I believe that in the next few years, we should be able to break through the black light transmission problem. So as to realize that any color can pass through black ink and there will be no hidden particles.

Niceone-Keypad hopes that this article can give you some technical help for users and projects. If you have technical questions, please contact us.

Do you have any questions, or would you like to speak directly with a representative?