Contact

Write to Us And We Would Be Happy to Advise You.

Do you have any questions, or would you like to speak directly with a representative?

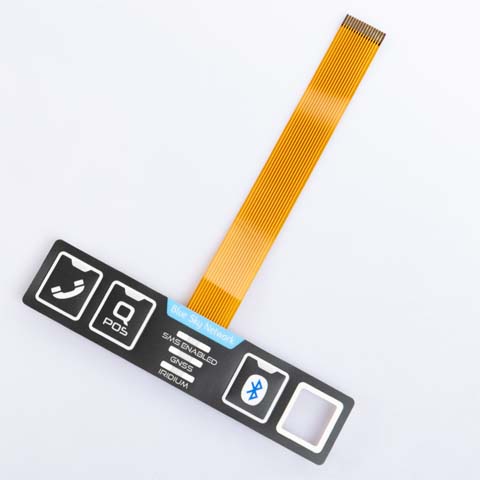

Electronic circuits FPCs are the core components of most electronic products. They often combine with electronic components such as ICs, resistors, conductive traces, Leds, and capacitors. It can also be called a soft board. Single panel and double panel in FPC are popular in Flat Membrane Switch side. But there are also applications of multi-panel and rigid-flex board.

The main raw materials of FPCs: 1. Raw material base material. 2. PI covering film. 3. Reinforcing sheet 4. Gold-plated material.

There are only two parts of the non-adhesive substrate consisting of copper foil and PI. The size and thickness are thinner, the heat resistance is better, and the chemical properties are more stable.

The choice of copper foil thickness is 1OZ, 0.5OZ and one-third OZ. In order to make products more competitive in the market, the market has even developed 1/4OZ. In the future, as the competition in the market becomes greater and the lines become thinner. Such products will be popular in the future.

Adhesive substrates are also the most common materials for FPCs: copper foil, adhesive and PI. There are three types of single-sided substrates, double-sided substrates and multi-sided substrates.

Reinforcing sheet: FR4, PI film or steel sheet.

For more detailed information, please contact Niceone-Keypad, we will reply you within 24 hours

For more information regarding flexible printed circuits, reach out to us today!

Do you have any questions, or would you like to speak directly with a representative?