Contact

Write to Us And We Would Be Happy to Advise You.

Do you have any questions, or would you like to speak directly with a representative?

By hqt

Backpanel membrane switches are a type of interface technology used in a variety of electronic devices, including medical equipment, consumer electronics, and industrial control systems. They are designed to provide a reliable and efficient way for users to interact with these devices, and offer a number of advantages over other types of input mechanisms.

In this article, we will explore the basics of back panel membrane switches, including their construction, functionality, and advantages. We will also discuss some of the most common applications for this technology, and provide some tips for choosing the right back panel membrane switch for your needs.

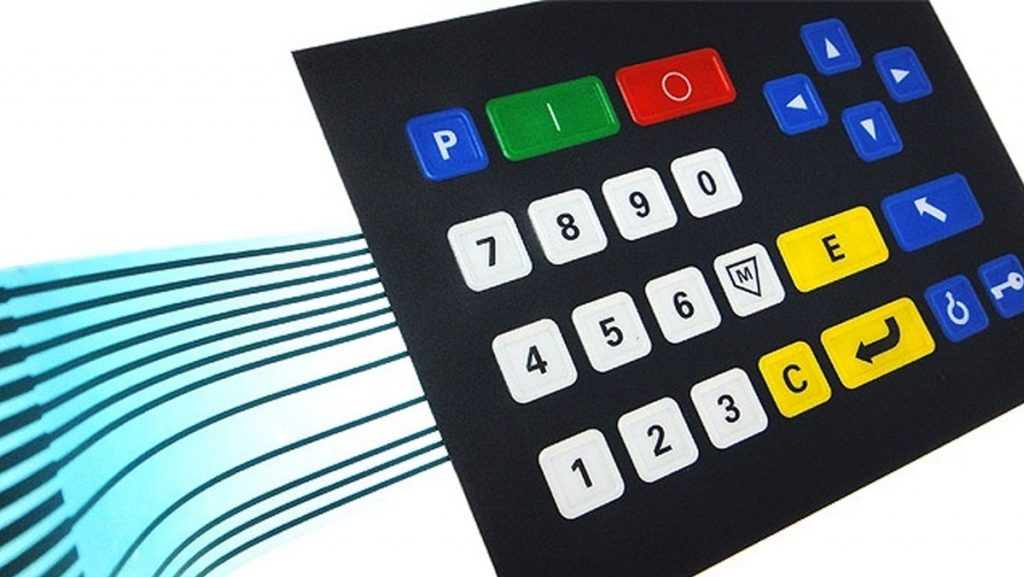

A back panel membrane switch is a type of user interface that is typically made up of multiple layers of thin, flexible materials. These layers are bonded together to create a durable and long-lasting switch that can be used to input commands into a device.

At the heart of a backpanel membrane switch is a layer of conductive material, typically made of copper or silver. This layer is used to transmit electrical signals from the user’s input to the device’s circuitry. When a user presses a button or touches a specific area of the membrane, the conductive layer is compressed, allowing electrical current to flow through it and trigger a specific action or command.

Backpanel membrane switches can be designed to be either tactile or non-tactile. Tactile switches provide a physical response when a user presses a button or touches a specific area of the switch. This feedback can be useful in situations where the user needs to know that they have successfully triggered a command. Non-tactile switches, on the other hand, do not provide any physical feedback, but can be more reliable and durable over time.

As mentioned earlier, backpanel membrane switches are typically made up of multiple layers of thin, flexible materials. The exact construction of the switch can vary depending on the specific application and design requirements, but most switches will include the following layers:

The functionality of a backpanel membrane switch can vary depending on the specific design and application. However, most switches will have some basic functionality in common.

When a user interacts with a backpanel membrane switch, they are typically applying pressure to a specific area of the switch, which compresses the spacer layer and allows electrical current to flow through the circuit layer. The circuitry on the circuit layer is designed to transmit this electrical signal to the device’s circuitry, which then interprets the input and triggers a specific action or command.

The functionality of backpanel membrane switches depends on the specific design and application. However, most switches share some common features and functions.

When a user interacts with a backpanel membrane switch, they apply pressure to a specific area of the switch, which compresses the spacer layer and allows electrical current to flow through the circuit layer. The circuitry on the circuit layer is designed to transmit this electrical signal to the device’s circuitry, which then interprets the input and triggers a specific action or command.

Backpanel membrane switches can be designed to have different types of inputs, including buttons, sliders, touchpads, and rotary switches. They can also incorporate additional features such as LEDs, backlighting, and haptic feedback.

One of the advantages of backpanel membrane switches is their versatility in terms of functionality. They can be designed to perform a wide range of tasks and can be customized to meet the specific needs of a particular application. For example, in medical equipment, backpanel membrane switches can be designed to provide tactile feedback for doctors and nurses, allowing them to input commands quickly and accurately, even in high-stress situations. In consumer electronics, backpanel membrane switches can be designed to incorporate touchscreens, providing users with a more intuitive and interactive experience.

Backpanel membrane switches offer a number of advantages over other types of interface technologies, including:

Backpanel membrane switches are used in a variety of applications, including:

Choosing the right backpanel membrane switch depends on the specific needs of the application. When selecting a switch, there are several factors to consider:

Do you have any questions, or would you like to speak directly with a representative?