Contact

Write to Us And We Would Be Happy to Advise You.

Do you have any questions, or would you like to speak directly with a representative?

By hqt

Niceone-Keypad believes that a good Membrane Keypad incorporates functionality, aesthetics, and the most appropriate cost considerations. Today, let us discuss in depth how each of these three aspects will affect users and the market.

Membrane Keypad has more options for ESD, Backlight, Waterproof, additional back plate plus screws and Doming design.

Let’s first talk about the role of this kind of function on the product.

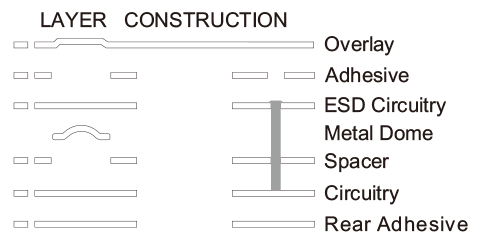

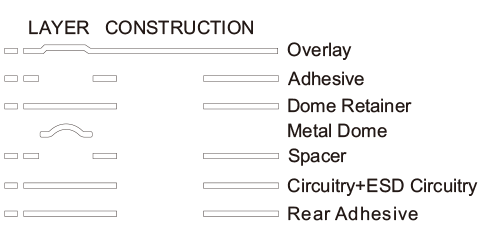

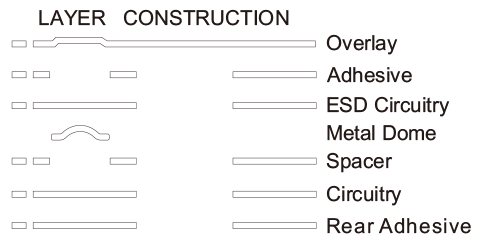

ESD (Electrostatic Discharge) / EMI (Electromagnetic Interface) / RFI (Radio Frequency Interface): Most Membrane Keypads have higher dielectric strength and higher volume resistivity. If the product is still affected by static electricity, then ESD/EMI/RFI is a very good choice.

There are also many choices of materials:

Foil: Material can choose PI, copper foil.

Transparent conductive ink: It is suitable for Membrane Keypad with a shielding structure on the window, but the cost will be more expensive than conventional ink.

Conventional silver oil ink: the most commonly used shielding material, which is conducive to cost saving and can meet the needs of customers.

Flex Copper with Printing Circuit Board as wiring: Direct shielding can be done using internally corroded structures. There is no need to print a shield on the fixed layer.

What conductor is used to connect the material of the shield structure to the ground wire.

Membrane Keypad needs to be divided into two situations.

Polyester as line:

Flex Copper and Printing Circuit Board as circuit:

The Backlight Membrane Keypad is designed in four ways. No matter which design is used, the Membrane Keypad can be used in a low-light environment, and it can also remind users of the key keys to play a warning role. And the Backlight Membrane Switch designed by Niceone-Keypad not only does not affect the Tactile Feedback of the product, but also illuminates the product more evenly and more strategically. Thanks to the close cooperation between Niceone-Keypad’s engineering team and material suppliers, we have designed a fully backlit membrane switch while maintaining the best tradition of Membrane Keypad – thin. You can also add backlit buttons, icons and logos required for product lighting. It is even possible to form various required colors through the cooperation of three-color lamps and ICs.

EL, Fiber Optical, LGF and regular LEDs light up.

Waterproof(IP67) Membrane Keypad

You must have encountered a lot of waterproof products in your life. And waterproofing in Membrane Keypad is usually inseparable from a term called IP liquid ingress protection mark. The waterproof Membrane Keypad needs to have several necessary points to do at the same time.

Additional enhancement options:

In many cases, Membrane Keypad will add screws with aluminum plate or choose FR4 and screws to increase its thickness so that it can be directly assembled with the product. The advantage of this is that it can greatly reduce the cost of foreign procurement and placement for customers.

Attached to the Doming Membrane Keypad design using the glue-drop technology of the silicone keyboard. Compared with the traditional Embossing Membrane Keypad, the Doming Membrane Keypad not only does not change the height of the embossing, but also has a recovery function, even if it is used for a long time, the tactile feedback will not deteriorate.

More importantly, it can make the product more aesthetic performance.

Membrane Keypad features more than your options, contact Niceone-Keypad and we will give you the best functional design advice for your product.

Do you have any questions, or would you like to speak directly with a representative?