Contact

Write to Us And We Would Be Happy to Advise You.

Do you have any questions, or would you like to speak directly with a representative?

By hqt

In the medical industry, medical equipment, operating table equipment, cardiac resuscitation equipment and other types of hand-held nurse call equipment use membrane switches to replace most of the mechanical switches. The main reason is the high reliability and technicality of membrane switches as keyboards and buttons, more and more membrane switches are being added to the medical industry. In the past ten years, Niceone-Keypad has developed many medical membrane switches and summarized more design experience. From the design of the hand to the design of the backlit form, we have broken through countless times.

Today we encountered a new project, how to make a Membrane Swtich that can still be used after sterilization and high pressure mechanical sterilization. The use and assembly of such membrane switches require a lot of testing such as high and low temperature cycle testing, 100 grid test and electrical performance test, etc. To ensure that medical type membrane switches can be used in extreme environments, high temperature and high pressure sterilization and routine use requirements. Therefore, we will analyze how to solve such products in this article. When giving a methodology to medical membrane switch design, we need a deeper understanding of autoclaves.

Autoclaves use high-temperature steam and adjust the internal pressure to make the temperature higher or even reach 120 degrees Celsius to sterilize various equipment for different times. Generally speaking, the autoclave takes a long time to reach 120 degrees Celsius. High pressure and high heat can destroy a large number of bacteria and viruses, which can be used repeatedly by medical staff.

In the cognition of most users, the normal operating temperature of mechanical switches and membrane switches is about 80 degrees Celsius. If the temperature is higher, the product will open, the adhesive tape material will lose its viscosity, and the polyester of the fixed layer will shrink. However, the disinfection of the medical environment may be as high as 120 degrees Celsius. At this time, because of the high requirements of operating rooms and inspection equipment, it is also to avoid the impact of bacteria on patients and staff. The disinfection equipment of medical equipment is generally an autoclave. This requires that the membrane switch needs to be repeatedly sterilized at 120 degrees Celsius without deformation and glue.

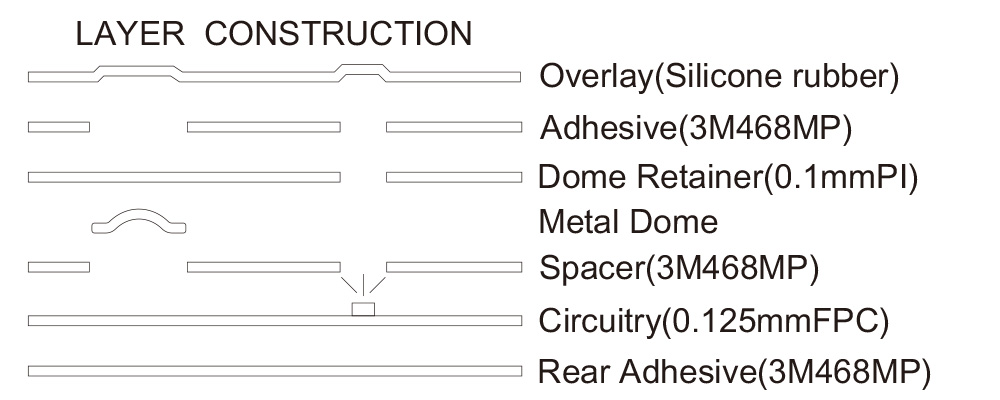

The operating conditions of the environment have been clearly defined as high temperature and high pressure. Then, each layer of the membrane switch needs to be explained separately, and the structural design requires more care. The size of the Membrane Switch also requires careful consideration. Some ICs and electronic components cannot withstand high temperature and high pressure, so they need to be carefully evaluated when purchasing.

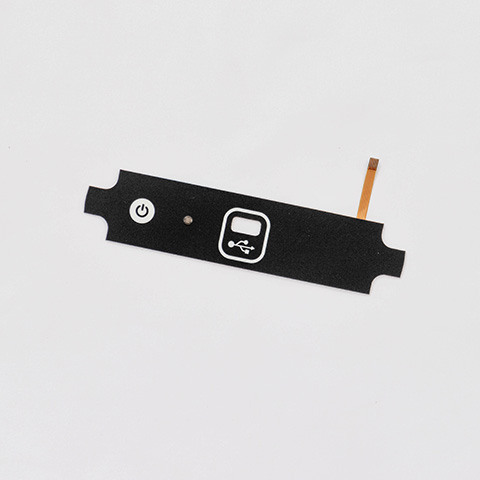

The traditional membrane switch panel material is Polyester or polycarbonate, there is no denying that these are good panel materials. But in this type of environment, it is directly passed, because at 120 degrees Celsius, the two materials will shrink and the panel will start to crack. Silicone Rubber Keypad as a silicone elastic silicone product, is well selected as the panel material choice. This is because Silicone Rubber Keypad medical grade silicone can be rated at 200 degrees Celsius or higher without problems. Therefore, the first choice of material for Niceone-Keypad is to use Silicone Rubber Keypad as the panel.

The adhesive material is very close to the problem of polyester and polycarbonate, and it is used in an environment of 85 degrees Celsius rather than higher, so engineers will consider high-temperature adhesive materials when designing to adapt to high temperature and high pressure conditions. There are many choices, but 3M468 is also a good material. Some adhesives are also available but the MOQ is higher, the cost is higher and the lead time is longer.

The fixed layer needs to consider PI, because the material of PI is also one of the materials of Flex Copper Circuit, and the temperature limit is far beyond 120 degrees Celsius, so it is also a very good choice as a fixed layer.

There are only two options for the membrane switch circuit: PCB or Flex Copper Circuit. Even at 120 degrees Celsius, the product line performance will not show any failures. This is because the polyester circuit will shrink when heated, and the ink will also be affected, resulting in overall problems with the circuit.

Common structures of membrane switch materials for sterilization and high pressure applications are summarized below:

Even when the structure is completed, we need to test and inspect it to ensure quality. Contact Niceone-Keypad, we will communicate with you more design solutions.

Do you have any questions, or would you like to speak directly with a representative?