Contact

Write to Us And We Would Be Happy to Advise You.

Do you have any questions, or would you like to speak directly with a representative?

By hqt

This project is one of our projects, and we are very grateful to the customer for agreeing to use this product as a case. The following will name the project A project.

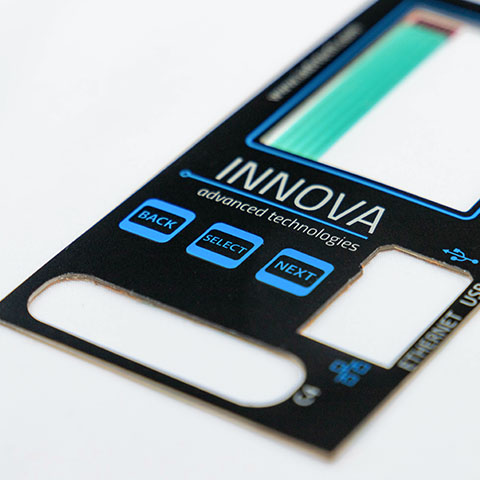

Project A is an assembly company in the United States. The customer discussed with us that the product will be used in the marine industry, but the waterproof performance of the product reaches IP67 and the panel selection needs to resist ultraviolet rays. But the LEDs of the light table are used.

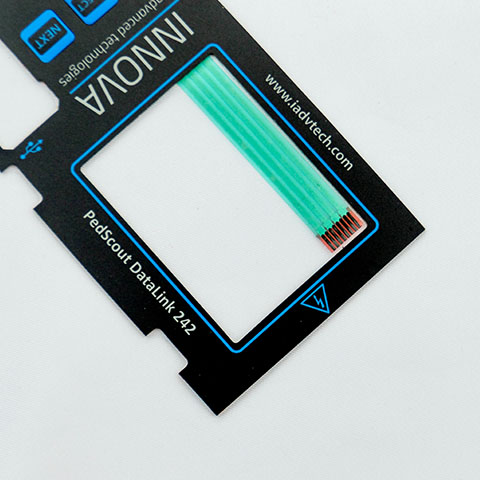

Niceone-Keypad in action: The engineering team communicates with the business team, customizing the drawings and needing to understand the customer’s needs. Choose Cotutec from the XE range of UV resistant materials. Structural selection of waterproof frame structure. The adhesive paper is selected as a material with high viscosity. At the same time, we choose Flex Copper circuit or PCB. We also purchase LEDs from Digi-Key to solve the problem.

Niceone-Keypad Action: Consultation with engineering team to produce samples using rapid manufacturing samples. Since we designed the waterproof structure in the early stage, XE material and high-viscosity material and these materials are in stock, we only need to modify the mold for sample production.

Fortunately, with quick sample preparation and third-party testing, waterproof performance is no problem. Sunscreen information needs to be provided by Kotutai.

Wait until the customer confirms. Our production team, QC team and engineering team will carry out the intersection of production documents, so as to make production with high yield, high quality and low consumption. It can also be said that it is faster and more economical, and its quantitative indicators are reflected in the input-output ratio. The QC team must do a good job in the quality management of the production process. It must start from the basic conditions, mine the data that affects the product quality, and use the quality data, equipment data, testing device data, measurement tool data, etc. of each process in the product production process. The factor analysis model uses clustering algorithm and association algorithm to build a traceability model, and through data training, the model can accurately trace the influencing factors of quality problems. At the same time, all products are packaged and shipped after testing.

At this time, customer A’s evaluation of us:

I was blown away by the quality of the product and the delivery was on time. Even if the accessories are not satisfied, you can quickly think of a solution without delaying the delivery. Hope to continue to develop new projects to cooperate with you next time.

Do you have any questions, or would you like to speak directly with a representative?