Contact

Write to Us And We Would Be Happy to Advise You.

Do you have any questions, or would you like to speak directly with a representative?

By hqt

Niceone-Keypad has been committed to developing and customizing membrane switches for different industries, and the most common industry is agricultural automation technology. Even in the face of any challenges, Niceone-Keypad is confident that the engineering team and business team can work together to provide the most suitable solution for the customer’s application and field of use. Niceone-Keypad will be made with care whether it is a small batch or a large batch of products.

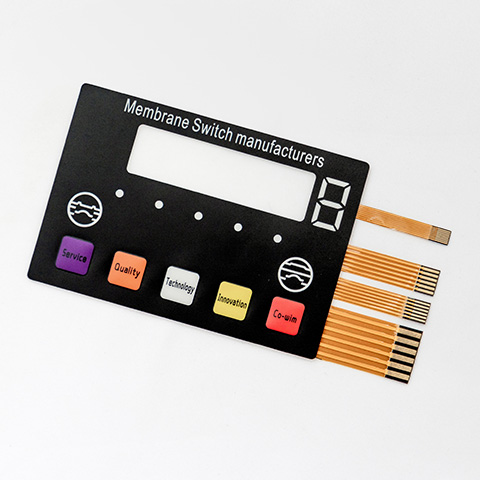

The following are examples of our design products for your convenience:

In agricultural applications, Membrane Switch usually encounters many problems as the main human-machine interface for agricultural operators. Membrane Switch is often an outdoor product in agriculture, which means that HMI needs to face various extreme environments such as solar radiation-ultraviolet rays, hot and cold outdoor temperatures and harsh outdoor environments.

The customer encountered a more serious design issue on top of other suppliers, whose supplier’s design repeatedly failed and failed to achieve the intended use case. So the client turned to Niceone-Keypad.

Niceone-Keypad’s QC team has carefully checked the customer’s samples and copywriting feedback to understand why the problem occurred

1. During the use of the product tape, the LEDs circuit has a short circuit problem due to the unbearable extreme temperature, which leads to the problem of water ingress after the glue is opened.

2. The design of the line outlet is not correct, it is better to use the surrounding closed form to design.

3. The color of the panel is slightly faded, which may be due to the lack of anti-ultraviolet materials.

These problems cause customers to increase a lot of after-sales costs, making customers less confident in them, in order to solve this problem quickly.

Niceone-Keypad’s solution is:

1. Change the inner material to 3M tape with better stickiness.

2. Seal the LEDs in package form after using Flex Copper Circuit.

3. Design pinouts with wraparound closures

4. The panel faded slightly because no UV-resistant material was used, so XEF150 was chosen to solve the problem.

| Customer samples | New design of Niceone-Keypad | New design result | |

| Panel material: | conventional polyester material | XEF150 | Perfectly resists the effects of UV rays on the product |

| Substrate material: | After testing, it can be used normally at 10-60 degrees Celsius. | Using 3M7959, 3M7961 and 3M468, it can be used in an environment of -20 to 60 degrees Celsius. | There is still no glue opening after high and low temperature cycle tests. |

| Circuits: | Polyester’s silver oil circuit | Flex Copper Circuit, and encapsulation technology | After the high and low temperature cycle test and the water cycle test, the sample still has no problems. Brightness is OK. |

| Design optimization: | – | While using the packaging technology for the LEDs, the waterproof frame structure was selected. | The waterproof structure reached IP67. |

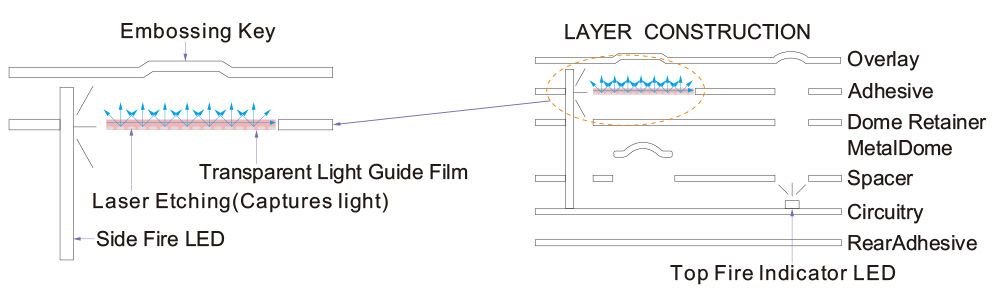

Most of the medical equipment is often used by hospital staff. It can be said that medical equipment is the weapon of medical personnel, so how to configure the weapons of medical personnel to increase their chances of winning on the medical battlefield is also from the Membrane Switch factory. Work. In this regard, Niceone-Keypad has improved and developed a new special lighting option – Backlight Membrane Switch. It achieves more uniform brightness and thicker thickness. Thinner and lower cost.

How is Niceone-Keypad implemented?

Design:

1. Niceone-Keypad uses ink with better light conductivity.

2. Reflective material is used to attach to the Flex Copper Circuit to enhance the light perception.

3. The design team has 12 years of experience in the arrangement of LEDs and the design of light guide points. So the most suitable LEDs will be placed in the most suitable place.

4. We will choose higher MCD LEDs to recommend to customers.

5. A more reasonable structure level avoids the problem of light leakage of the product. Such as the choice of black tape and so on.

Cost

1. Adopt the latest light guide layout technology and software, and use printing dots instead of molds to arrange light guide points. Therefore, the mold cost can be greatly reduced.

2. Fewer LEDs can be used to light up the product because the light guide points are more concentrated. Save a lot of welding costs and LEDs costs

3. Since Niceone-Keypad has enough experience to design and produce Backlight Membrane Switch as an integrated factory, the trial and error cost is lower.

4. Niceone-Keypad purchased a laser plotter for drawing design so this is also the benefit of an integrated factory.

5. Have automatic production equipment such as automatic shrapnel placement machine, automatic punching machine, etc.

| Overview of Backlight Membrane Switch from Niceone-Keypad | Traditional Backlight Membrane Switch | |

| Brightness is more uniform and brighter | √ | |

| lower cost | √ | |

| more beautiful design | √ | |

| thinner thickness | √ | |

| Production cycle | 3-4Weeks | 5-6Weeks |

Niceone-Keypad has been developing membrane switches suitable for various applications, and a professional team will follow up in the process of quotation, design and production. We hope to produce high-quality products seriously so that customers’ hidden costs can be greatly reduced. Contact Niceone-Keypad and we will get back to you as soon as possible.

Do you have any questions, or would you like to speak directly with a representative?