Design of Silicone Keypads for Hazardous or Difficult Situations

Introduction

Silicone keypads are an essential component in various industries, particularly in hazardous or difficult situations. These keypads provide a reliable and durable interface for controlling machinery and equipment, even in challenging environments. In this article, we will delve into the design aspects of silicone keypads for hazardous or difficult situations, exploring their features, benefits, and applications. Whether you’re an engineer, designer, or industry professional, understanding the intricacies of silicone keypad design will empower you to make informed decisions and ensure optimal performance in demanding scenarios.

Table of Contents

-

1. Understanding the Importance of Silicone Keypads in Hazardous Situations

Silicone keypads play a crucial role in hazardous situations by providing a reliable interface for operators to control machinery and equipment. The design of these keypads takes into account the unique challenges posed by such environments, ensuring optimal performance and safety.

What Makes Silicone Keypads Ideal for Hazardous Environments?

Silicone keypads are highly suitable for hazardous environments due to their exceptional resistance to extreme temperatures, chemicals, and physical stress. The flexible and robust nature of silicone makes it an ideal material for keypads that can withstand demanding conditions.

How Does the Design of Silicone Keypads Enhance Safety?

The design of silicone keypads incorporates features that enhance safety in hazardous situations. These include tactile feedback, which provides users with a clear indication of button actuation, and backlighting options for improved visibility in low-light conditions. Additionally, silicone keypads can be customized with various safety symbols and markings, aiding operators in quickly identifying critical functions.

Key Considerations for Designing Silicone Keypads in Hazardous Situations

When designing silicone keypads for hazardous environments, several factors must be considered. These include temperature and environmental conditions, chemical resistance, and ergonomics. By carefully addressing these considerations, engineers can create keypads that meet the specific requirements of the application while ensuring user safety and satisfaction.

-

2. Factors Influencing the Design of Silicone Keypads for Difficult Environments

The design of silicone keypads for difficult environments is influenced by several factors that directly impact their performance and durability. Understanding these factors is vital in creating keypads that can withstand challenging conditions effectively.

Temperature and Environmental Conditions

In difficult environments, temperature fluctuations and extreme weather conditions can adversely affect the performance of keypads. Silicone keypads are designed to withstand a wide range of temperatures, from sub-zero cold to scorching heat, ensuring reliable operation regardless of the surroundings.

Chemical Resistance and Durability

In certain industries, exposure to chemicals and harsh substances is a common occurrence. Silicone keypads are known for their exceptional resistance to chemicals, making them an ideal choice for applications where contact with corrosive agents is expected. Furthermore, the durability of silicone keypads allows them to endure physical stress and frequent use, ensuring longevity and consistent performance.

Ergonomics and User-Friendliness

Designing silicone keypads with ergonomic considerations in mind is crucial for user comfort and efficiency. Well-placed buttons, appropriate spacing, and intuitive layouts contribute to a user-friendly experience, minimizing errors and enhancing productivity. Additionally, the tactile feedback provided by silicone keypads further improves usability by providing users with a satisfying and responsive interface.

-

3. Key Features of Silicone Keypad Design

The design of silicone keypads incorporates various features that contribute to their overall functionality, reliability, and user experience. These features encompass material selection, button layout, and customization options.

Material Selection and Composition

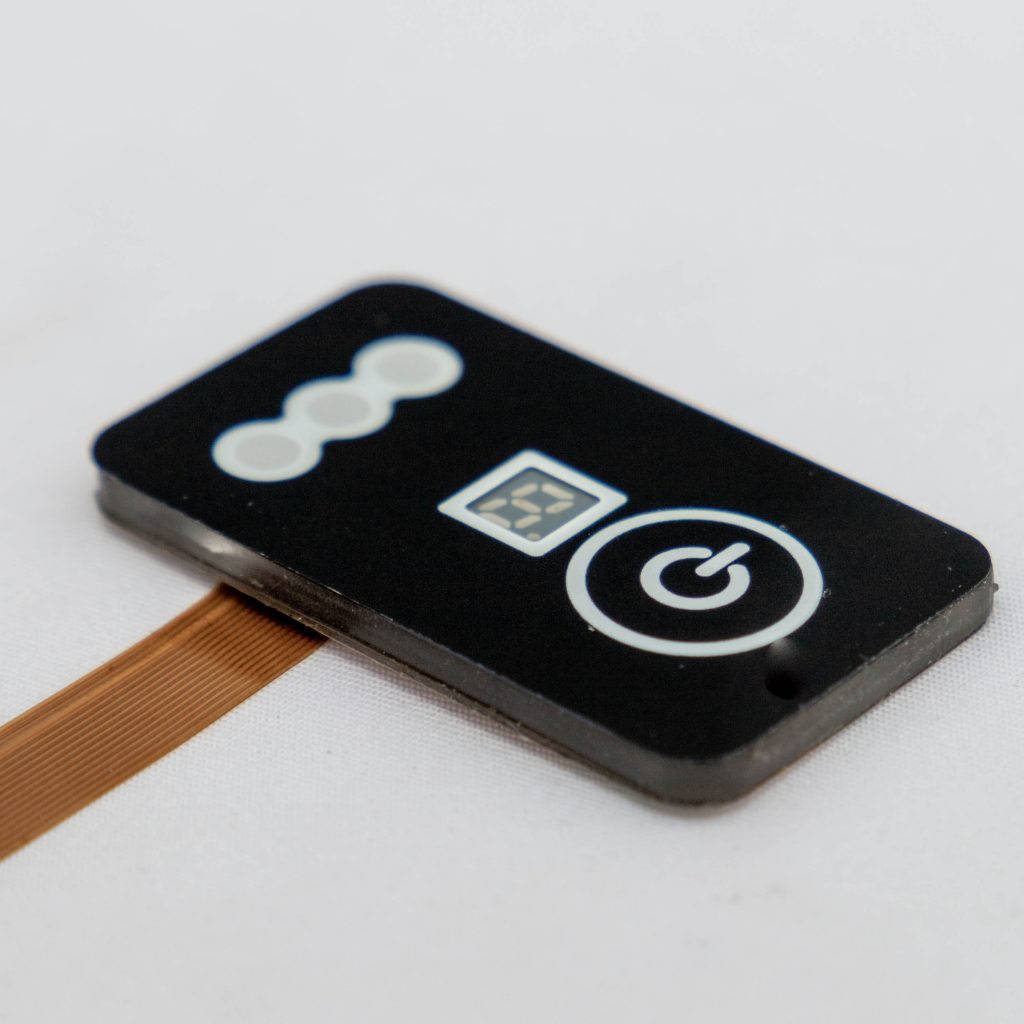

Silicone keypads are typically made from a combination of silicone rubber and conductive materials. The silicone rubber provides flexibility, durability, and resistance to environmental factors, while the conductive materials facilitate electrical conductivity for reliable actuation. The composition of the keypad material is carefully formulated to achieve the desired tactile feel and longevity.

Button Layout and Configuration

The layout and configuration of buttons on silicone keypads are essential considerations. Engineers must ensure that the buttons are logically placed for ease of use and that they are appropriately sized to prevent accidental actuation. The number and arrangement of buttons depend on the specific application and functional requirements.

Backlighting and Customization Options

Backlighting is a valuable feature in silicone keypads, particularly in low-light or dimly lit environments. It enhances visibility and readability, allowing users to operate the keypads with ease. Additionally, silicone keypads offer customization options such as embossing, laser etching, and color coding, enabling manufacturers to tailor the keypads to their unique branding and functional needs.

-

4. Applications of Silicone Keypads in Hazardous or Difficult Situations

Silicone keypads find applications in various industries where hazardous or difficult situations are prevalent. The robust design and versatile features of silicone keypads make them indispensable in controlling machinery and equipment in challenging environments.

Industrial Machinery and Equipment

In industrial settings, silicone keypads are widely used in control panels for heavy machinery and equipment. Their resistance to extreme temperatures, chemicals, and physical stress ensures reliable operation, even in demanding conditions. The tactile feedback and customization options further enhance safety and ease of use in hazardous environments.

Medical and Healthcare Devices

Medical and healthcare devices often require user interfaces that can withstand sterilization processes, cleaning agents, and frequent use. Silicone keypads are an ideal choice for such applications due to their chemical resistance, durability, and ease of cleaning. From diagnostic equipment to patient monitoring devices, silicone keypads play a vital role in ensuring accurate and efficient healthcare operations.

Military and Defense Systems

In military and defense systems, reliability and ruggedness are of utmost importance. Silicone keypads are designed to meet the stringent requirements of these industries, offering exceptional resistance to harsh environmental conditions, shock, and vibration. Their user-friendly interface and backlighting options make them ideal for mission-critical applications where quick and accurate inputs are necessary.

-

5. Frequently Asked Questions (FAQs)

- Can silicone keypads withstand extreme temperatures?

Yes, silicone keypads are designed to withstand extreme temperatures, both high and low. They can operate reliably in environments ranging from -50°C to +200°C, ensuring optimal performance in challenging conditions.

- Are silicone keypads resistant to chemicals?

Absolutely. Silicone keypads exhibit excellent resistance to a wide range of chemicals, including solvents, acids, oils, and cleaning agents. This makes them highly suitable for applications where exposure to corrosive substances is expected.

- How long do silicone keypads typically last?

The lifespan of silicone keypads depends on various factors such as usage frequency, environmental conditions, and maintenance. However, with proper care and regular cleaning, silicone keypads can last for several years, providing reliable performance throughout their lifespan.

- Can silicone keypads be customized to fit specific requirements?

Yes, silicone keypads offer a high level of customization. Manufacturers can tailor the button layout, symbols, backlighting, and overall design to meet the specific requirements of their applications. This versatility allows for seamless integration and user satisfaction.

- Are silicone keypads easy to clean and maintain?

Yes, silicone keypads are easy to clean and maintain. Their smooth surface allows for effortless wiping and removal of dirt, dust, and contaminants. Additionally, their resistance to chemicals ensures that they can be safely cleaned with various cleaning agents without causing damage or deterioration.

- What industries benefit the most from silicone keypads?

Several industries benefit greatly from the use of silicone keypads, including automotive, aerospace, medical, industrial, and defense. These keypads provide reliable and durable control interfaces in hazardous or difficult situations, contributing to the overall safety and efficiency of operations in these industries.

-

6.Conclusion

The design of silicone keypads for hazardous or difficult situations requires careful consideration of various factors, including temperature, chemical resistance, and user experience. By selecting appropriate materials, configuring button layouts, and incorporating customization options, engineers can create silicone keypads that excel in challenging environments. Their applications in industries such as industrial machinery, medical devices, and military systems highlight the importance of silicone keypads in ensuring reliable control and enhanced safety. With their exceptional performance and versatility, silicone keypads continue to be a go-to choice for industries operating in hazardous or difficult situations.