Design Guidelines for Membrane Keypad:

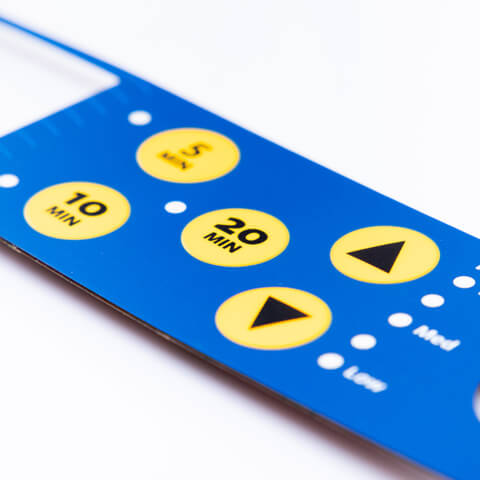

Membrane Keypad is an important part of HMI. A perfect Membrane Keypad can not only play a role in brand promotion, but even attract the attention of the public. To make a perfect Membrane Keypad needs to pay attention to some small details, when the details are handled properly, then your Membrane Keypad will stand out in the market. Niceone-Keypad’s team organizes these points to facilitate user query.

-

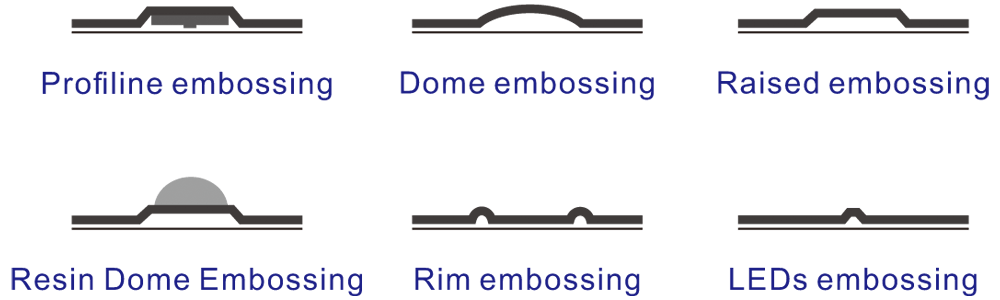

1. What kind of embossing can Membrane Keypad do?

There are six types of regular embossings for the Membrane Keypad. Choosing the right Embossing will improve handling, provide great Tactile Feedback and also bring unique aesthetics.

Height Embossing Features Dome embossing 0.3-1.5mm Circular Embossing, diameter range 8-14mm Rim embossing 0.2-0.4mm The middle part is the surface of the Flat, with only Embossing all around LEDs embossing 0.3-0.5mm Usually used when the LEDs are too high and the overall thickness of the product is insufficient, LEDs Embossing will be used Raised embossing 0.3-0.5mm For special embossing, you need to contact Niceone-Keypad to discuss whether it can be customized. Profiline embossing 1-1.5mm Increase product travel with Tactile Dot for enhanced feel. Resin Dome Embossing 1.5±0.5 The transparent Resin keys are formed by special materials. -

2. What type of technology is the Membrane Keypad suitable for?

Membrane Keypad uses many technologies, the conventional ones are Capacitive, illuminated, PCB(FR4) Doming, Silicone Rubber Keypad, Copper Circuit.

Capacitive Membrane Keypads: Niceone-Keypad has customized a variety of Capacitive Membrane Keypads for different input units. These products are easy to clean, scratch resistant, and can be customized with an anti-glare effect. Suitable for long-term cleaning.

What are Capacitive Membrane Keypads?

Capacitive Membrane Keypads are products that enable product functionality by changing the capacitance of its smooth surface. There are many choices of panel materials such as glass, plastic, polyester or Polycarbonate. Due to the protection of the material, the non-conductive surface forms a perfect barrier after separating the conductive surface from the operator. Compared with traditional mechanical switches, which cannot form a partition, the lifespan is shortened, which is also a major advantage of Capacitive Membrane Keypads.

The Tactile Feedback of Capacitive Membrane Keypad is 0, mainly through visual (feedback of LEDs brightness) and auditory signals (buzzer built in the product, etc.) to judge whether the product starts to work.

Illuminated Membrane Keypad:

Niceone-Keypad produces this type of product in four ways: EL, LEDs, Fiber Optical or Light Guide film. These switches allow you to operate in the dark. Niceone-Keypad’s Illuminated Membrane Keypad offers the following advantages:

- MOQ is 1pcs, no matter the quantity is more or less, Niceone-Keypad will also help customers to develop and produce carefully.

- Energy saving.

- Some products and logos can achieve Deadfront effect, using Digital printing and Screen printing.

- Able to operate in the dark or low-light environment.

- The brightness of LEDs can be adjusted through IC design.When the Illuminated Membrane Switch has sufficient light, its light source will be affected and its light intensity will be greatly reduced. For more details please click Backlight Membrane Switch..

PCB Membrane Keypad:

As the circuit of the Membrane Keypad, the most obvious advantage is that the PCB can be used as a support board. Niceone-Keypad is even required by customers to assemble screws and nuts in the PCB board to become a general existence similar to AL panel. When the number of customers is small and a support board is required, PCB Membrane Keypad can be considered as one of the options. The second obvious benefit is that the electrical performance is more stable and lower in resistance than the conventional polyester silver oil circuit.

Silicone Rubber Membrane Keypad:

Using Silicone Rubber Membrane Keypad as the panel of the product is not only lower cost in mass production, but also the waterproofness and easy cleaning of Silicone Rubber Keypad are far better than mechanical switches.

Copper Circuit Membrane Keypad(FPC):

The main feature of Copper Circuit Membrane Keypad is that the circuit is Copper Circuit. This type of circuit has the difference of single-sided, double-sided and multi-sided, and has the characteristics of bending resistance and low circuit resistance. One thing that is even better than the printed silver oil circuit is that all kinds of electronic components can be mounted on the circuit and not only limited to LEDs.

-

3. How does Membrane Keypad increase Tactile Feedback?

The Tactile Feedback of the Membrane Keypad is also very important for the operator. Because a good Tactile Feedback can not only reduce user errors, but also allow users to obtain clear feedback and provide a more positive user experience.

So how to increase the Tactile Feedback of Membrane Keypad?

There are four general practices for Niceone-Keypad to increase tactile feedback:

- Choose a suitable Snap Dome.

- Select Hardware Embossing Tooling. The Embossing formed in this way will have a better stroke, and at the same time, the height will be relatively high.

- Add a touch point above the Snap Dome. Generally used with Backlight Membrane Keypad or PU Dome Membrane Keypad.

- Structural optimization: such as the air vents, the thickness of the surface glue and the thickness of the Overlay, etc. will also affect the Tactile Feedback.

Someone once asked our team why there are still some Membrane Keypads without Tactile Feedback on the market?

This is because of specific product, interaction preferences, and cost considerations.

Product specific: The product requirement for the mixing room is to be quiet, giving user feedback without ticking.

Interaction preference: Some products, Capacitive Membrane Keypad, consider non-tactile feedback.

Cost considerations: Tactile Feedback Membrane Keypad requires more assembly parts and assembly procedures. Some users also choose Non-Tactile Feedback due to cost considerations.

-

4. Window color selection for Membrane Keypad?

Membrane Keypad is generally set transparent color according to the color of the display screen, printing transparent color or transparent.

- The color of the display screen is the color of the 8-character tube, and the transparent color printed on the panel window is the color of the 8-character tube light.

- Transparent, depending on the panel material, print window oil, matte or transparent material.

-

5. What is the color selection for the LEDs window of the Membrane Keypad?

LEDs are one of the important accessories of the Membrane Keypad. Choosing the right LEDs window will improve the product shape score, and it can also hide the LEDs and the bottom wiring. So what is the choice of window color:

- Raw material transparency: cost saving.

- Transparent white: Effective hidden wiring and LEDs make the product more aesthetic.

- Transparent color of LEDs color: At this time, due to the low lumen of some LEDs, it is necessary to use white LEDs with high lumen to light the window.

-

6. Do users need to consider the working environment of the Membrane Keypad?

Membrane Keypad needs to be considered from design to production process including cost, appearance and the most realistic working environment.

Common work environments that manufacturers need to inform and even consider include the following:

- Whether it is used in a high voltage environment

- Whether it is used in a high humidity environment

- Indoor or outdoor use

- Temperature conditions

- Corrosive solutions, etc.

- Static environment

Why do these environments need to be considered?

Niceone-Keypad has found that under these circumstances, the wrong choice of material or structural design can cause irreversible electrical damage to the Membrane Keypad. Choosing the wrong material can render the product inoperable at high and low temperatures. If you choose too expensive materials, it may cause excess quality. In order to avoid such problems, Niceone-Keypad provides users with material selection and structure suggestions for these environments. This will help you learn more about your own product.

- Whether it is used in a high voltage environment

High-voltage environments need to consider the humidity of the air. Membrane Keypads are prone to silver migration if the air is humid. To avoid this type of problem you need to do:

- At this time, it is necessary to consider converting the circuit from Silver Circuit to Flex Copper Circuit or Printing Circuit Board.

- Consider the waterproof frame structure. The main function is to prevent the oxidation of moisture and lines, resulting in short circuit and other phenomena.

- Whether it is used in a high humidity environment

The main problem caused by the high humidity environment is that the line is oxidized after contacting with water, resulting in a short circuit of the line.

- At this time, it is necessary to consider converting the circuit from Silver Circuit to Flex Copper Circuit or Printing Circuit Board.

- Consider the waterproof frame structure. The main function is to prevent the oxidation of moisture and lines, resulting in short circuit and other phenomena.

- The vent hole must be inside the product instead of the outside. If the vent hole is selected outside, it will cause water to enter the product and corrode the product.

- Indoor or outdoor use

The problem that is often considered in indoor use is anti-glare, and glare is one of the reasons for operating errors.

For outdoor use, UV rays need to be considered. Ultraviolet rays can easily cause the panel ink to peel off and other phenomena.

- There are two methods of anti-glare: A. Use anti-glare materials such as Autotype F series and V series materials, both of which have Matte.B. Use anti-glare coating, which can also be used Effective anti-glare。

- There are many methods of anti-ultraviolet: you can choose Silicone Rubber Keypad with anti-ultraviolet. UV-resistant panel materials, etc.

- Temperature conditions

Temperatures such as extreme cold and extreme heat can easily cause embrittlement and delamination of the adhesive tape, which can cause the entire product to become unusable or even cause major operational accidents. If the temperature conditions are relatively warm, conventional adhesive tape can be used without causing excess quality.

- Choose the right 3M Adhesive, because the operating conditions of 3M Adhesive can generally be -20 – 80 degrees Celsius, while the conventional Nitto and even the domestic Dt Adhesive cannot be used at -20 degrees Celsius, and the routine is 10-60 degrees Celsius. But the temperature can be considered to use this type of tape in this range. It is also conducive to cost control.

- Corrosive solutions, etc.

Corrosive solutions can cause damage to the panel while attacking the wiring to the bottom.

- Corrosion-resistant Polyester material or Polycarbonate material can be selected.

- Select Silicone Rubber Keypad as the panel material.

- Static environment

The biggest problem with electrostatic environments is that they interfere with electrical functions and cause damage to LEDs.

- Selecting an ESD shield can effectively solve such problems.

- You can also choose a waterproof frame structure to further prevent static electricity problems.

-

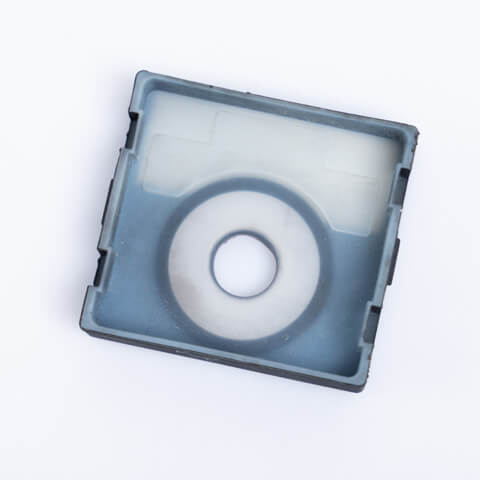

7. The latest technology of Membrane Keypad-Gloss technology or Resin Dome.

Niceone-Keypad has been devoted to researching new Membrane Keypad technology, fortunately, Niceone-Keypad has not only successfully developed Light Guide Film type backlight Membrane Keypad, Fiber Optic Membrane Keypad in the past 10 years, but also successfully developed Gloss Technology Also known as Resin Dome or Doming Membrane Keypad.

Gloss Technology is a Membrane Keypad that Niceone-Keypad uses special ink and glue to form a special texture. Its Buttons are not only shiny, but also of high thickness, elegant and high quality. There is a clear difference from the regular Membrane Keypad. The term can also be referred to as Doming or Resin Dome, and the processing of this type of technology is carried out in the area of the key or customer needs. The general shape can be produced as long as there is no angle of 90°. It also has the function of self-healing, also called self-resilience.

What are the common shapes of Gloss Technology?

The advantages are:

Reduce operational errors. This is due to Gloss Technology’s ability to effectively protrude key locations.

Products are more aesthetic and elegant, differentiating your products from your competitors.

Dust and splash proof.

-

8. What are the benefits of the waterproof design of the Membrane Keypad?

The waterproof design of the Membrane Keypad has two main benefits. The most obvious is that it can be waterproof as its name. But the second benefit is less known, which can improve the role of the ESD shielding layer, thereby improving the anti-static ability.

-

9. What type of anti-static is the Membrane Keypad?

ESD, RFI, waterproof frame, PI isolation film, etc.