Introduction to Silicone Rubber Keypad

Silicone Rubber Keypad has been widely used in all walks of life due to its excellent performance since its inception. Niceone-Keypad In order to let people who like them know more about the product, we wrote an article hoping to help more people understand this product:

-

1. What is the common design and product name of Silicone Rubber Keypad?

-

2. What are the main raw materials of Silicone Rubber Keypad?

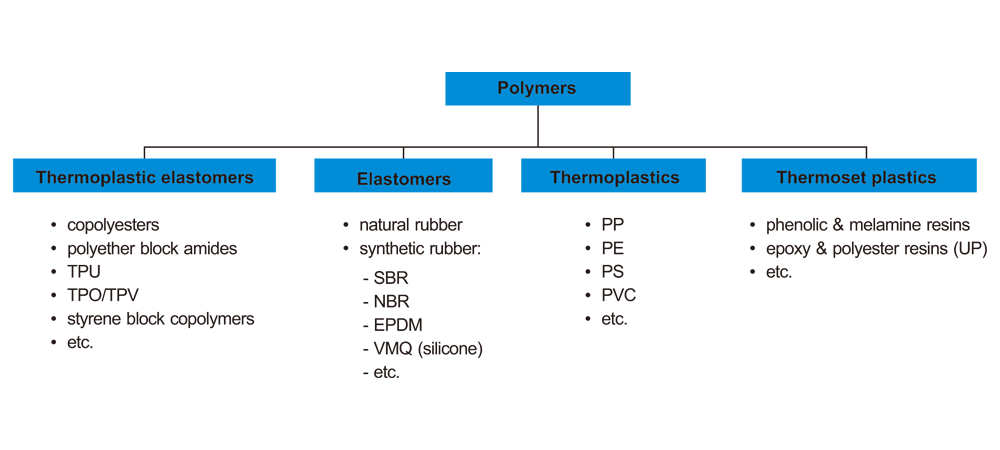

The raw material of Silicone Rubber Keypad is Silicone. Silicone is an elastomer material and is a subgroup of Polymers. Natural rubber and synthetic rubber are also a category of Polymers. It is mainly made from rubber juice as a tree. Synthetic rubber is a product of organic chemistry. The raw material is crude oil. The conventional hardness is generally 50-80A. If the hardness of the Silicone Rubber Keypad is too high, it will have a higher defect rate, and the relative cost will be higher.

-

3. What are the common undercut designs?

Mounts of Silicone Rubber Keypad include: Pull-Through, Wrap-Around, Push-Through, Pull-Snap, Push-Snap. If the diameter of the undercut can be as large as possible, it is more convenient for production.

-

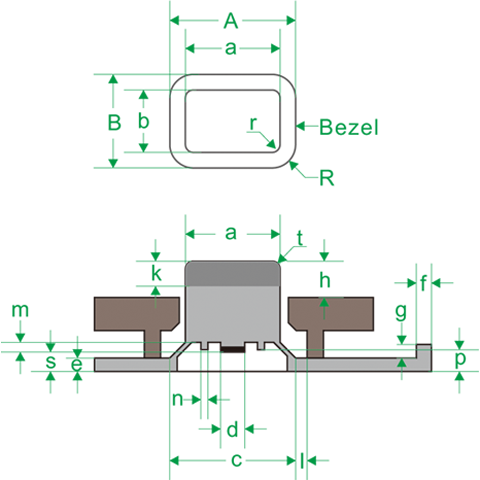

4. Some technical parameters of Silicone rubber keypad?

Silicone Rubber Keypad has some size restrictions. If the product cannot meet the requirements, production may not be possible. The following are some general product size restrictions.

In applications where the keyboard is completely sealed, guide holes are not allowed, and ventilation can be carried out through the ventilation path between the keys, that is, the ventilation openings should not lead to the outer edge of the keyboard.

-

5. The dimensional error of Silicone Rubber Keypad should be followed?

The size error of Silicone Rubber Keypad should follow:

Dimension

Tolerance

Inches MM Inches MM 0 – .987 0 – 25 0.005 0.13 .998 – 1.460 25.1 – 37 0.008 0.2 1.461 – 1.971 37.1 – 50 0.01 0.25 1.972 – 2.444 50. – 1-62 0.012 0.31 2.445 – 2.956 62.1 – 75 0.015 0.38 2.957 – 3.428 75.1 – 87 0.017 0.44 3.429 – 3.940 87.1 – 100 0.02 0.5 3.491 – 5.908 100.1 – 150 0.024 0.62 5.909 – OVER 150.1 – OVER 0.50% 0.50% -

6. About the buttons of Silicone Rubber Keypad:

There are generally six types of Silicone Rubber Keypad shapes: Double Cone, Double Bell, Flat Bell, Flat Cone, Single Cone, Single Bell. The difference lies in the stroke, load and range of use.

Double Cone: Force between 30-90g is one of the smallest load ranges among all products. Stroke Range 2.0-4.0mm. The service life is up to 2,000,000 times. Commonly used equipment: computer or typewriter, etc.

Flat Bell: The load of 20-80g can be the smallest and the life span is the longest. Respectively 20-80g, the life span is 30,000,000 times. The most commonly used industries are telephones, mobile control equipment, automation equipment, and agricultural equipment.

Single Cone: Force is generally between 30-250G, and Stroke Range is between 0.7-2.0mm. The most commonly used equipment is telephone, or testing equipment, automation equipment, navigation equipment and so on. The service life can be up to 2,000,000 times.

Single Bell: Force is generally between 30-200G, and Stroke Range is between 1.0-3.0mm. The most commonly used devices are telephones, mobile devices, or test equipment. The service life can be up to 5,000,000 times.

Double Bell: Force is generally between 30-250G, and Stroke Range is between 1.0-2.5mm. The most commonly used equipment is telephone, or test equipment. The service life can be up to 2,000,000 times.

Flat Cone: It is a conventional button type, the force is generally 30-350G, and the Stroke Range is between 0.5-3mm. The most commonly used industries are telephones, mobile control equipment, automation equipment, etc. The service life can be as high as 200,000 times.

-

7. Silicone Rubber Keypad-STABILIZER (STOP BAR) and ROCKER KEY

-

8. Silicone Rubber Keypad conventional industry standard specifications

Travel 0.8 – 1.5 mm Force 60 – 300 grams Tactile Response Yes Life Cycles 1,000,000 Operating Temperature -40° to + 150° C Storage Temperature -50° to + 170° C Dielectric Strength >1 min @ 500 VRMS ESD Breakdown >20KV/MM Contact Bounce <5MS Contact Resistance <200 Ohms KEYTOP RADIUS FOR SILKSCREEN PRINTING:

R v = D + 1 mm, R30 min

R x = D + 1 mm, R20 min

-

9. What are the light guide designs of Silicone Rubber Keypad?

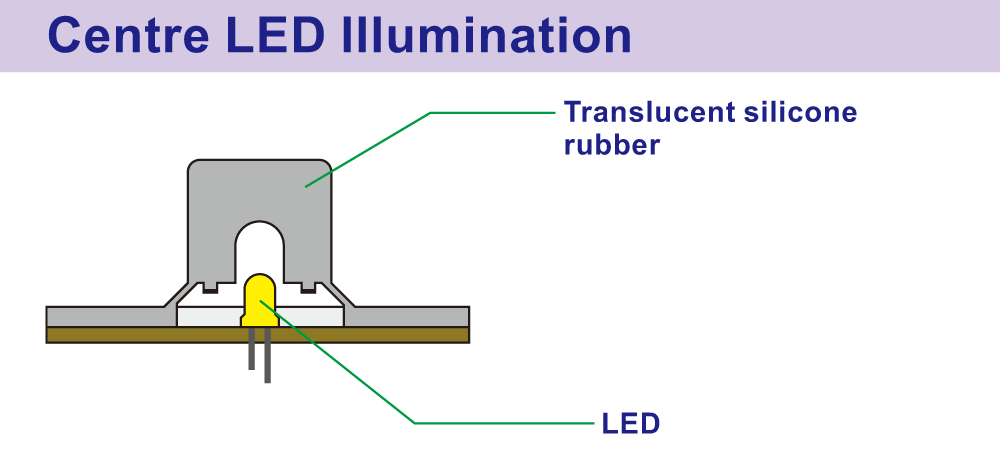

- The LEDs are placed in the center of the button.

This type of installation of LEDs is suitable for Silicone Rubber Keypads that have a small space and require buttons to emit light. At the bottom of the buttons, you need to choose Circular Ring or Semi-Circular Ring to avoid LEDs. If you need a Metal Dome driver, you need to consider choosing a Metal Dome with holes. And there are many forms of the same type of backlight. Suitable for laser carving Silicone Rubber Keypad or Silicone Rubber Keypad for transparent silicone printing opaque pigments.

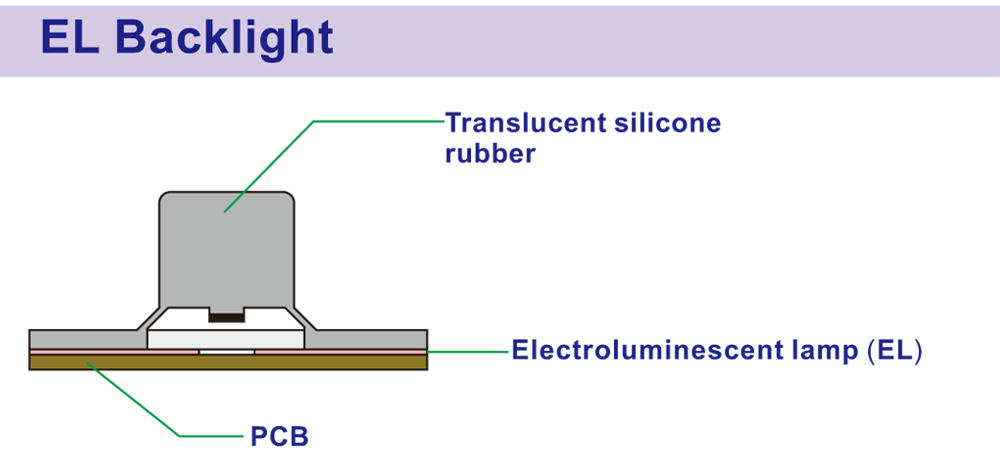

- EL backlight:

The EL backlight emits a single color, and only one type of color can be selected, and the brightness is relatively more uniform. Silicone Rubber Keypad that is suitable for large-area luminous logos and fonts at the same time. However, higher power drive is required and the life span is only 2000-3000h. If you want a longer life span, you can consider the form of optical fiber, but the cost is relatively high.

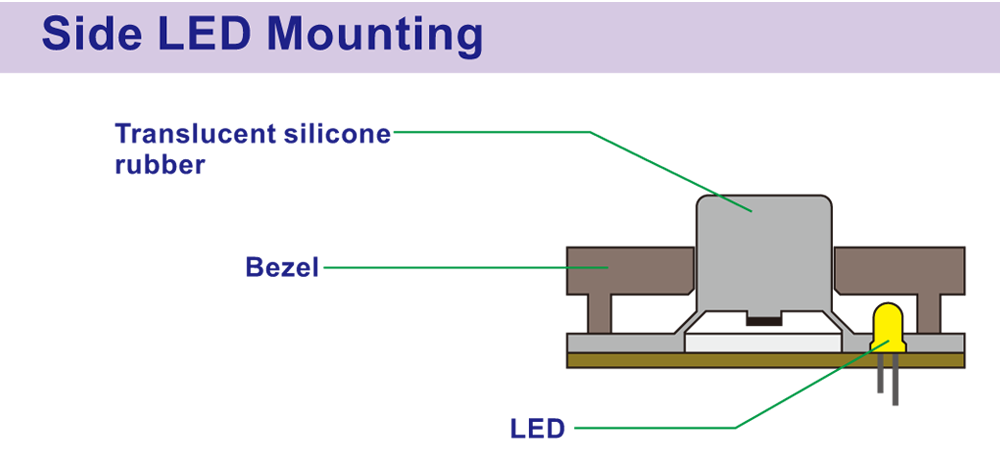

- Side LEDs Mounting

One of the most common forms of Silicon Rubber Keypad backlight. Use a metering lamp or a forward lamp to guide the light to the transparent silicone. Thus forming a backlight. Longer life up to 10,000H. Silicone Rubber Keypad suitable for the backlight of the entire button.

-

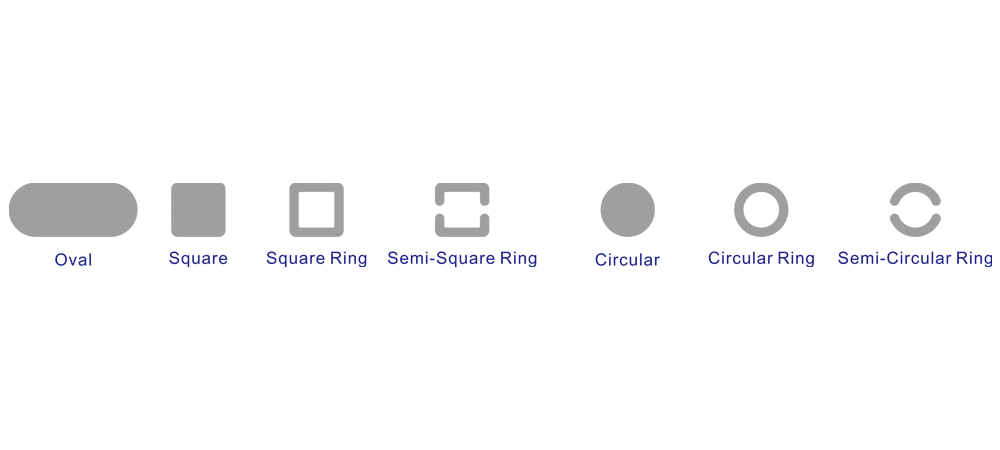

10. What are the common carbon ring shapes of Silicone Rubber Keypad?

Common carbon ring forms are Circular Circular Ring Semi-Circular Ring Oval Square Square Ring Semi-Square Ring. Niceone-Keypad recommends the use of carbon pellets. Because the stability of the carbon particles is better and the resistance is lower, and over time, the carbon oil will not peel off due to driving and cause the loss of function.

Contact Surface of PCB: Carbon Gold Gold Type Design Shape Contact Resistance Life Cycles Max. Rating Carbon Pill Circular <200 Ω <150 Ω > 5 Mio 30 VDC / 5 mA Carbon Dip Printing No limit <600 Ω 150-300 Ω 1-3 Mio 30 VDC / 3 mA Metal dome No limit <35 Ω 1-10 Ω > 0.5 Mio 42 VDC / 30 mA Metal Pill Circular <25 Ω 1-10 Ω > 5 Mio 100 VDC / 100 mA Metal Powder Pill Circular <150 Ω 10 – 50 Ω 1 – 5 Mio 35 VDC / 35 mA Polydome Circular <35 Ω 1 – 20 Ω > 1 Mio 45 VDC / 20 mA Low Resistance Carbon Pill Circular < 35 Ω < 10 Ω > 5 Mio 30 VDC / 5 mA Standard Size Of Carbon Pill and Carbon Dip Printing.

The size of Carbon Pill is generally 2.5-10mm, in increments of 0.5 mm. If the Carbon Pill of special shape is selected or the size deviates from this range, the price is relatively high.

Carbon Dip Printing has no restrictions. But the resistance is higher and the life is shorter.

The Surface of Contact Options:

Silicone Rubber Keypad is often combined with three circuits to form a complete electronic product.

Contact Options Material Contact Surface Thickness Stability Stability of Welding Components Resistance Rigid FR4, CEM1, etc. Gold, Nickel, Carbon 0.4-2mm Excellent Well Low Flexible Polyimide with Copper Gold, Nickel 0.125-0.175mm Excellent Well Low Flexible Polyester Carbon, Silver, Carbon-Silver-Mixture or UV ink 0.1-0.188mm Well Non-solderable Components <150Ω The conductive contact area in each direction should be 0.5 mm min. Larger than the conductive contact area under the Silicon Rubber Keypad button to prevent poor contact. For joystick keys and keys with metal bullets, Niceone-Keypad needs to verify the customer’s drawings and documents to make a judgment.

-

11. What are the printing details of Silicone Rubber Keypad silk screen fonts?

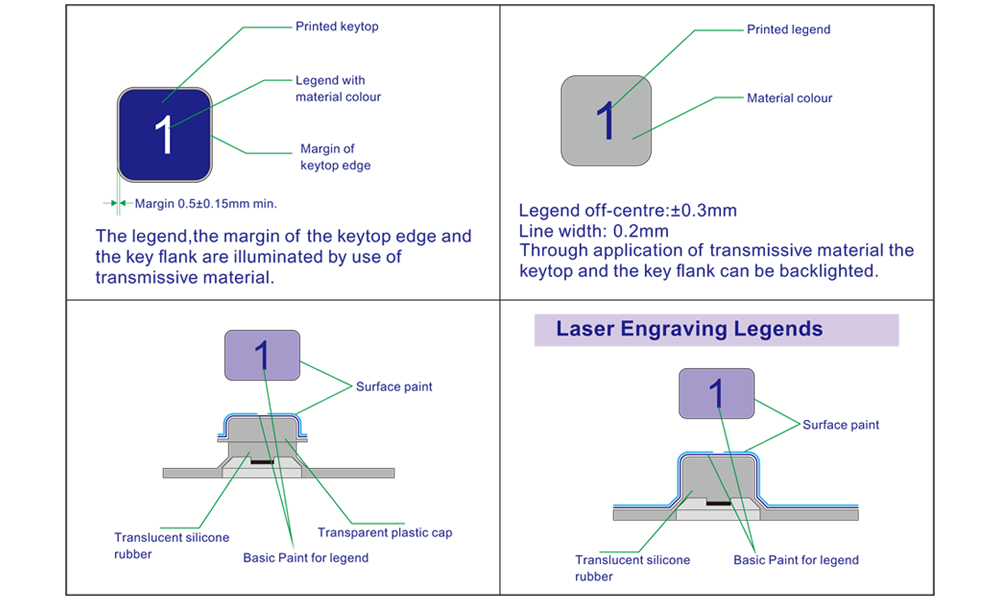

The standard rubber keyboard just prints graphics through Screen Printing or pad printing. If the Silicone Rubber Keypad does not need to use backlight technology, the standard Silicone Rubber Keypad can already meet the needs of many companies. This is a cheap and simple way to create letters, numbers, and special characters on the keys. If customers have higher usage requirements or aesthetic realization, they can use molded rubber backlights, and the rubber must be laser etched: this is a newer and more advanced method of producing backlight nomenclature, graphics, indicators, etc. Laser Engraving Lengends mainly use high-power lasers to remove one or more layers of paint on the Silicon Rubber Keypad. Backlight Silicone Rubber Keypad usually uses translucent milky white or transparent Silicone Rubber raw materials, and then sprays various opaque colors, and uses laser technology to etch and burn the paint in selected areas. After removing the paint, it will reveal the translucent layer underneath. The result is the formation of contrasting translucent and opaque colors, so that the backlight area has higher clarity, brightness and visibility. Use different backlight technologies after reaching the translucent layer of the keyboard.

The two commonly used ways for Silicone Rubber Keypad to display different logos and fonts are Laser Engraving Legends or Screen printing. So where are their detailed requirements? Or what are the characteristics?

Laser Engraving Legends uses a laser to evaporate the printed coating to reveal the material color of the Silicone Rubber Keypad. The most used color is transparent material or transparent white. There are two common designs

Screen Printing mainly uses screen printing or pad printing to form logos and fonts in different colors. Generally speaking, there are some restrictions on printing: Legend off-center: + /-0.3 mm. Line width≥0.2mm. If it is full-page printing, there will also be some restrictions on use. There is 0.5mm +/- 0.15mm min from the printing surface to the edge.

What are the advantages of Silicone Rubber Keypad?

Application industries of Silicone Rubber Keypad: aerospace, automotive, agriculture, manufacturing, life, food and beverage, rail transit, natural gas. Why is it so brilliant in these industries? The reason is because it has many good advantages. Among them, Niceone-Keypad lists these advantages for users to check.

- Silicone Rubber Keypad is more cost-effective: The unit price of Silicone Rubber Keypad is relatively lower, but the mold cost is more expensive than Membrane Switch Panel. It is a good choice when the number of products is large.

- Backlight design: EL, optical fiber or LEDs can be used for color lighting. Generally, the additional process is laser etching the pigment of Silicone Rubber Keypad keys or the pigment of etching plastic keys. If LEDs are used as the option of backlighting, different keys are also added with different backlight colors.

- Durability: Regardless of the extreme outdoor environment, fire resistance and antibacterial properties are achievable. Silicone Rubber Keypad has excellent resistance to extreme temperatures and aging. Even Silicone Rubber Keypad has excellent chemical resistance and moisture resistance. There will be no problems even if the regular button functions are used millions of times.

- Personalized customized design: One of the most prominent advantages of Silicone Rubber Keypad is that it can be customized according to different needs.

- Spray PU or hand-feeling oil can be used to protect the printed content, thereby increasing the life and durability of the product.

- Use a waterproof design, that is, a surround type to increase the waterproof level, thereby preventing liquid, dust and gas from damaging the buttons at the bottom of the Silicone Rubber Keypad.

- Different keys can use Silicone Rubber materials with different hardness, which makes the product with different hand feelings.

- The Silicon Rubber Keypad can be printed in different ways through Screen printing, including product LOGO, key text, etc.

- Excellent tactile feedback: The geometry of the keyboard webbing can create a 3-dimensional keyboard with firm tactile response and longer switch travel. The driving force and switch stroke can be customized according to your requirements.

How does Silicone Rubber Keypad work?

When users and operators press the switch of the Silicon Rubber Keypad, the Web will bend and spring back. The carbon particles under the Silicone Rubber Keypad button are in contact with the silver oil circuit or the gold-plated layer on the bottom and then conduct to realize the electrical function, or the silica gel particles squeeze the Metal Dome under the button to connect with the bottom circuit to form an electrical function.

-

12. What are the additional processes for Silicone Rubber Keypad?

Customers once asked Niceone-Keypad, is there any way to make Silicone Rubber Keypad more competitive in the market? The answer is yes. Silicone Rubber Keypad can make it more competitive in the market through some additional processes. In order to facilitate customers and engineering to understand its process. Niceone-Keypad gives the following suggestions.

Resin Dome is also called PU Dome: it is glued to the top of the Silicon Rubber Keypad or at the logo to make the product more three-dimensional while increasing the aesthetic performance of the product. At the same time, it can reduce the abrasion of silk screen fonts.

Some engineering design and production of Resin Dome need to pay attention to 4 points, which is conducive to reducing defects.

- Ensure that all appliances are clean during the glue dispensing process, and operate in a dust-free environment, so as not to affect the appearance of impurities, ripples, and pits on the surface after the glue is cured.

- The humidity of the epoxy working environment is controlled within 65%. It is not recommended to dispense glue on rainy days, because when the air humidity is too high, the fog in the air will directly cause the surface of the glue to oxidize and even fail to solidify.

- The proportion of glue must be accurately weighed, and the glue must be stirred evenly, otherwise the glue will not be cured completely and will be cured for a long time.

- Silicone products with strict dripping effect should be placed in the area to be dried, and the temperature should be controlled between 28°-40°.

Laser carving button design: Use laser to engrave the area that needs light. The engraving content is generally the text or logo above the button. This type of Silicone Rubber Keypad is good for use in low-light environments. At the same time, LEDs can be used to achieve multiple colors of buttons.

Laser carving button design some design points:

- Translucent colors need to be printed thinner, and the raw materials should be Silicone Rubber kypad with better light transmittance, such as gas rubber. This helps to increase the brightness.

- The Silicone Rubber Keypad after laser engraving needs to be sprayed with PU ink or hand-feeling oil to protect the laser engraved area from being peeled off easily.

- The printing ink with strong adhesion and high temperature resistance should be selected, so that the pattern carved out by laser will be relatively more accurate and perfect.

P+R design: Use the plastic shell additional glue and the buttons of the Silicone Rubber Keypad to form P+R. While the product is more aesthetic, the plastic shell can also protect the keys of the Silicone Rubber Keypad and extend the product life. Choosing the right plastic shell can also increase the feel of the Silicone Rubber Keypad.

P+R design should pay attention to:

- Special P+R glue should be selected, which is beneficial to prolong the adhesion and prolong the life of the product.

- If the silk-screened content is on the Plastic shell part, it is necessary to spray hardened ink to protect the printed content without fading.

- If the printed content is above the Silicone Rubber Keypad, it is better to use high-transparent materials for the Plastic part to display the product text and logo.

Combination of Membrane Switch and Silicone Rubber Keypad: Due to the durability of Silicone Rubber Keypad, extremely high cost-effectiveness and suitable design can increase the waterproof effect of Membrane Switch by a level. Therefore, Silicone Rubber Keypad is often combined with Membrane Switch to form a complete Silicone Rubber Keypad. For more information, please go to the page for more information.

-

13. How to quickly design a complete Silicon Rubber Keypad?

Is there any way from design to production that can speed up and save a lot of time and cost? The answer is yes. If you can understand the information, Niceone-Keypad can design drawings within three days, and complete samples or bulk goods within 15-20 days.

- Need to understand the use environment of the product: In this way, Niceone-Keypad can choose the right material in the shortest time

- The production of molds requires complete 3D files

- Does Buttons need backlight technology?

- Color number of button printing: RAL, PANTONE or master samples are all available. Material colour(s) in RAL, Pantone, Legend colour(s) in RAL, Pantone.

- Contact type

- Life in cycles as minimum

- Stroke S2 in mm with tolerance of ± 0.1 mm

- Snap Ratio in% with tolerance of ± 10%

- Actuation force F1 in CN with tolerance

With enough information, Niceone-Keypad will be able to save a lot of time and cost so that it can be shipped to you as quickly as possible. If all the information is not enough, Niceone-Keypad needs 3D files for product evaluation and customize it for you.

-

14. How to clean Silicone Rubber Keypad?

Over time, the user’s grease, environmental dust or accidental dumping of chemicals will accumulate on the Silicone Rubber Keypad, so that the Silicone Rubber Keypad will affect the operator’s use, thereby reducing the user’s efficiency. If the dust in the environment accumulates on the Silicon Rubber Keypad too much, it will even cause the circuit board under the Keypad to be corroded and cause a short circuit function. And cleaning the Silicone Rubber Keypad at the right time will help extend the life of the product. So how to clean it up?

If the Silicone Rubber Keypad is removable:

- Remove the Silicon Rubber Keypad from the electronic accessories.

- If the surface of the Silicone Rubber Keypad is not particularly greasy and only accumulates dust, you can first use a feather duster to clean the surface dust.

- The Silicone Rubber Keypad has a lot of dirt, so it needs to be soaked in warm water and wiped off with toothpaste and dried.

- It is also a good choice to wipe dust and dirt with white electric oil or alcohol attached to the top of the silk cloth. As alcohol has a better volatilization degree, it is easier to volatilize than water, so as to prevent the liquid from corroding electronic parts. But also need to pay attention not to use too much alcohol, otherwise the alcohol will cause the material structure to be destroyed and yellow.

If it is a non-removable type of Silicone Rubber Keypad, you need to consider using filling air for frequent cleaning instead of accumulating excessive dirt and shortening the life of the Silicone Rubber Keypad.